Lincoln Aviator: Front Suspension - RWD / Removal and Installation - Shock Absorber and Spring Assembly

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

NOTE: Removal steps in this procedure may contain installation details.

-

Remove the retainers and remove the cross brace.

.jpg) |

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTE: If equipped with dynamic suspension.

Disconnect the dynamic suspension electrical connector unclip and position the harness aside.

.jpg) |

-

NOTICE: The front suspension height sensor must be disconnected from the lower control arm prior to servicing suspension components or damage to the suspension height sensor and/or the vehicle dynamic suspension system may occur. The sensor will need to be recalibrated after reassembly.

NOTE: If equipped with dynamic suspension.

-

Disconnect the ride height sensor electrical connector.

-

Remove the ball stud from the lower control arm and position the front height sensor arm aside.

-

Disconnect the ride height sensor electrical connector.

.jpg) |

-

NOTICE: Do not use power tools to remove or install the stabilizer bar link nuts. Damage to the stabilizer bar link ball joints and boots may occur.

NOTE: The stabilizer bar links are designed with low friction ball joints that have a low breakaway torque.

NOTE: Use the TORX PLUS® holding feature to prevent the ball stud from turning while removing or installing the stabilizer bar link nut. Torx® and TORX PLUS® is a reg. tm of Acument Intellectual Properties, LLC.

Remove and discard the upper stabilizer bar link nut and position aside the stabilizer bar link.

.jpg) |

-

Remove and discard the lower arm mounting bracket pinch bolt.

.jpg) |

-

NOTICE: Use a prying device, flat headed screw driver or separator fork to separate the lower arm bracket from the shock absorber and spring assembly. Do not open the joint more than approximately 2mm. Damage to lower arm bracket may occur.

Spread the opening to loosen the lower arm mounting bracket from the shock absorber and spring assembly.

.jpg) |

-

Separate the front shock absorber and spring assembly from the lower arm mounting bracket.

.jpg) |

-

NOTICE: Never allow the knuckle to hang from the upper and lower control arms or damage to the ball joints can occur.

NOTE: Take care not to damage coating on suspension components.

Support the wheel knuckle assembly using mechanic's wire.

.jpg) |

-

Remove and discard the front shock absorber and spring assembly upper bolts.

.jpg) |

-

Remove the front shock absorber and spring assembly.

.jpg) |

Installation

-

-

Position the front shock absorber and spring assembly.

-

NOTE: Only tighten the bolts finger tight at this stage.

Install the new shock absorber and spring assembly upper mount bolts.

-

Position the front shock absorber and spring assembly.

.jpg) |

-

NOTE: Make sure that the mating faces are clean and free of foreign material.

Clean the lower arm mounting bracket bore and clean the threads of debris. If necessary, locate the prying tool as shown in graphic. Do not open the joint more than approximately 2mm.

.jpg) |

-

NOTICE: Care must be taken not to damage the shock absorber and spring assembly sharkfin bracket.

NOTE: Locate the praying tool below the sharkfin bracket. The prying tool should only be contacting the lower arm mounting bracket.

Insert the shock absorber and spring assembly into the lower arm mounting bracket.

.jpg) |

-

NOTICE: Use care when inserting the shock absorber and spring assembly into the lower arm bracket bore or damage to the sharkfin bracket may occur.

NOTE: Make sure that shock absorber and spring assembly is fully seated in the lower arm bracket bore.

Pry open the lower portion of the lower arm mounting bracket to allow the shock absorber and spring assembly to fully seat in the bracket bore.

.jpg) |

-

Install the new lower arm mounting bracket pinch bolt.

Torque: 59 lb.ft (80 Nm)

.jpg) |

-

Tighten the new shock absorber and spring assembly upper mount bolts.

Torque: 41 lb.ft (55 Nm)

.jpg) |

-

NOTICE: Do not use power tools to remove or install the stabilizer bar link nuts. Damage to the stabilizer bar link ball joints and boots may occur.

NOTE: The stabilizer bar links are designed with low friction ball joints that have a low breakaway torque.

NOTE: Use the TORX PLUS® holding feature to prevent the ball stud from turning while removing or installing the stabilizer bar link nut. Torx® and TORX PLUS® is a reg. tm of Acument Intellectual Properties, LLC.

Position the stabilizer bar link and install the new front stabilizer bar link upper nut..

Torque: 129 lb.ft (175 Nm)

.jpg) |

-

NOTICE: The front suspension height sensor must be disconnected from the lower control arm prior to servicing suspension components or damage to the suspension height sensor and/or the vehicle dynamic suspension system may occur. The sensor will need to be recalibrated after reassembly.

NOTE: If equipped with dynamic suspension.

-

Connect the ball stud to the lower control arm and tighten the front height sensor arm bolt.

Torque: 80 lb.in (9 Nm)

-

Connect the ride height sensor electrical connector.

-

Connect the ball stud to the lower control arm and tighten the front height sensor arm bolt.

.jpg) |

-

NOTE: If equipped with dynamic suspension.

Connect the dynamic suspension electrical connector and clip the harness into the body.

.jpg) |

-

Install the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Install the cross brace and the retainers.

Torque: 22 lb.ft (30 Nm)

.jpg) |

-

Check and if necessary adjust front camber.

Refer to: Front Camber Adjustment (204-00 Suspension System - General Information, General Procedures).

-

Calibrate the suspension system. Connect the scan tool

and carry out the Ride Height Calibration routine. Follow the scan tool

directions.

Removal and Installation - Lower Arm Bracket

Removal and Installation - Lower Arm Bracket

Special Tool(s) /

General Equipment

Flat Headed Screw Driver

Vehicle/Axle Stands

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems...

Removal and Installation - Shock Absorber and Spring Assembly - Vehicles With: Air Suspension

Removal and Installation - Shock Absorber and Spring Assembly - Vehicles With: Air Suspension

Removal

WARNING:

Vent all air pressure from the air suspension system prior

to disconnecting or removing any air suspension components. It is

dangerous to remove air suspension components while under pressure...

Other information:

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Rear Bumper

Removal NOTE: Removal steps in this procedure may contain installation details. All vehicles Remove the rear bumper cover. Refer to: Rear Bumper Cover (501-19 Bumpers, Removal and Installation). Vehicles without trailer tow package On both sides...

Lincoln Aviator 2020-2026 Service Manual: Disassembly and Assembly - Driveshaft Universal Joint

Special Tool(s) / General Equipment 205-086 (T74P-4635-C) Installer/Remover, C-Frame and Screw Materials Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B DISASSEMBLY NOTICE: Do not, under any circumstance, clamp the driveshaft assembly in the jaws of a vise or similar holding fixture...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Description and Operation - Jacking and Lifting

- Remove and Reinstall the Battery

- Interior Lamps

- New on site

- Most important about car

Fastening the Seatbelts

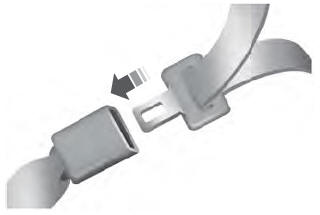

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.