Lincoln Aviator: Intake Air Distribution and Filtering - 3.0L EcoBoost/3.0L EcoBoost – Hybrid (BQ) / Removal and Installation - Air Cleaner Outlet Pipe RH

Removal

NOTICE: The turbocharger compressor vanes can be damaged by even the smallest particles. When removing any turbocharger or engine air intake system component, ensure that no debris enters the system. Failure to do so may result in damage to the turbocharger.

NOTE: Removal steps in this procedure may contain installation details.

Upper air cleaner outlet pipe

-

-

Loosen the clamps and remove the upper air cleaner outlet pipe.

Torque: 42 lb.in (4.8 Nm)

-

Loosen the clamps and remove the upper air cleaner outlet pipe.

.jpg) |

- Loosen the clamps and remove the CAC inlet pipe.

.jpg) |

- Loosen the clamp remove the air cleaner outlet pipe.

.jpg) |

Lower air cleaner outlet pipe

-

Remove the front undershield.

Refer to: Engine Front Undershield (501-02 Front End Body Panels, Removal and Installation).

-

-

Detach the clips.

-

Remove the nut.

Torque: 25 lb.in (2.8 Nm)

-

Detach the clips.

.jpg) |

-

NOTE: Use a 15mm socket located on the cast hex feature to rotate the drive belt tensioner counter-clockwise to release the belt.

-

Rotate the accessory drive belt tensioner clockwise.

-

Position the accessory drive belt aside.

-

Rotate the accessory drive belt tensioner clockwise.

.jpg) |

-

- Disconnect the A/C wiring harness electrical connector.

-

Detach the wiring harness retainer.

-

Remove the lower bolt from the A/C compressor.

Torque: 18 lb.ft (25 Nm)

.jpg) |

-

-

Disconnect the electrical connector.

-

Remove the bolts and position aside A/C compressor.

Torque: 18 lb.ft (25 Nm)

-

Disconnect the electrical connector.

.jpg) |

-

Remove the bolts from the lower air cleaner outlet pipe.

Torque: 93 lb.in (10.5 Nm)

.jpg) |

Installation

-

Inspect the turbocharger or engine air intake system components and clean, if necessary.

-

NOTE: All FEAD components and fasteners must be installed and torque before belt installation.

NOTE: Check the A/C Compressor clutch assembly and crankshaft vibration damper assembly after installation. Lumps in the belt surface indicate ribs are out of pulley grooves and not fully seated in the A/C Compressor clutch assembly and/or crankshaft vibration damper assembly.

After installation, make sure the accessory drive belt is correctly seated on all pulleys.

.jpg) |

-

To install, reverse the removal procedure.

Removal and Installation - Air Cleaner Outlet Pipe LH

Removal and Installation - Air Cleaner Outlet Pipe LH

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Removal and Installation - Charge Air Cooler (CAC)

Removal and Installation - Charge Air Cooler (CAC)

Removal

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system...

Other information:

Lincoln Aviator 2020-2026 Owners Manual: Rear View Camera

WARNING: The rear view camera system is a reverse aid supplement device that still requires the driver to use it in conjunction with the interior and exterior mirrors for maximum coverage. WARNING: Objects that are close to either corner of the bumper or under the bumper, might not be seen on the screen due to the limited coverage of the camera system...

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Floor Console

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: Removal steps in this procedure may contain installation details. Remove the front seats. Refer to: Front Seat (501-10A Front Seats, Removal and Installation)...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Anti-Theft Alarm

- Keyless Entry

- Configuring The Head Up Display

- New on site

- Most important about car

Fastening the Seatbelts

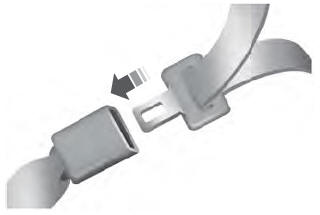

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.