Lincoln Aviator: Front Suspension - AWD / Removal and Installation - Front Lower Arm

Special Tool(s) / General Equipment

.jpg) |

204-592 Separator, Lower Arm Ball Joint TKIT-2006C-FFMFLM TKIT-2006C-LM TKIT-2006C-ROW |

| Vehicle/Axle Stands | |

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

-

Measure the distance from the center of the hub to the

lip of the fender with the vehicle in a level, static ground position

(curb height).

.jpg) |

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

NOTICE: Do not use power tools to remove or install the lower arm outboard nut. Damage to the ball joint or ball joint seal may occur.

NOTE: Use the TORX PLUS® holding feature to prevent the ball stud from turning while removing or installing the lower arm outboard nut. Torx® and TORX PLUS® is a reg. tm of Acument Intellectual Properties, LLC.

Remove and discard the front lower arm outboard nut.

.jpg) |

-

Remove the front halfshaft.

Refer to: Halfshaft (205-04 Front Drive Halfshafts, Removal and Installation).

-

NOTICE: Do not use a hammer, prying device, or separator fork to separate the ball joint from the wheel knuckle. Damage to the ball joint or ball joint seal may occur.

NOTICE: Use care when releasing the lower arm and wheel knuckle into the resting position. Damage to the ball joint or ball joint seal may occur.

Separate the front lower arm from the wheel Knuckle.

Use Special Service Tool: 204-592 Separator, Lower Arm Ball Joint.

.jpg) |

-

Remove and discard the front lower arm-to-frame bolt and remove the front lower arm.

.jpg) |

Installation

NOTICE: Tighten the suspension fasteners with the weight of the vehicle on the wheels and tires or use a suitable jack to raise the suspension to curb height or damage to the bushings may occur.

-

NOTE: Make sure that the mating wheel knuckle face is clean and free of foreign material.

Before installing a new front lower arm, inspect the knuckle to make sure it is clean and free of foreign material.

.jpg) |

-

NOTE: Only tighten the nuts and bolts finger tight at this stage.

Position the front lower arm and install the new front lower arm-to-frame bolt.

.jpg) |

-

NOTICE: Do not use power tools to remove or install the lower arm outboard nut. Damage to the ball joint or ball joint seal may occur.

NOTE: Use the TORX PLUS® holding feature to prevent the ball stud from turning while removing or installing the lower arm outboard nut. Torx® and TORX PLUS® is a reg. tm of Acument Intellectual Properties, LLC.

-

Attach the front lower arm to the wheel knuckle.

-

Install the new front lower arm outboard nut.

Torque: 76 lb.ft (103 Nm)

-

Attach the front lower arm to the wheel knuckle.

.jpg) |

-

Install the front halfshaft.

Refer to: Halfshaft (205-04 Front Drive Halfshafts, Removal and Installation).

-

Use a suitable jack to raise the suspension until the

distance between the center of the hub and the lip of the fender is

equal to the measurement taken during removal (curb height).

Use the General Equipment: Vehicle/Axle Stands

.jpg) |

-

NOTICE: Tighten the suspension fasteners with the weight of the vehicle on the wheels and tires or use a suitable jack to raise the suspension to curb height or damage to the bushings may occur.

NOTE: Only tighten the nuts and bolts when the suspension is in the normal drive position.

Tighten the front lower arm-to-frame bolt and nut.

Torque: 221 lb.ft (300 Nm)

.jpg) |

-

Install the wheel and tire.

Refer to: Wheel and Tire (204-04A Wheels and Tires, Removal and Installation).

-

Check and if necessary adjust front toe.

Refer to: Front Toe Adjustment (204-00 Suspension System - General Information, General Procedures).

Refer to: Front Toe Adjustment - Vehicles With: Adaptive Steering (204-00 Suspension System - General Information, General Procedures).

-

If equipped with dynamic suspension, calibrate the

suspension system. Connect the scan tool and carry out the Ride Height

Calibration routine. Follow the scan tool directions.

Description and Operation - Front Suspension - Overview

Description and Operation - Front Suspension - Overview

Overview

The AWD front suspension consists of the following components:

Front and rear lower arms

Rear lower arm ball joints

Stabilizer bar, bushings and links

Ride height sensors (Vehicles with Continuously Controlled Damping (CCD) Suspension)

Passive or dynamically controlled shock absorber and spring assembly (Continuously Controlled Damping (CCD))

Upper control arms

Wheel bearings and wheel hubs

Wheel knuckles

Wheel studs

The

front suspension uses a double ball joint short long arm suspension

system...

Removal and Installation - Front Stabilizer Bar

Removal and Installation - Front Stabilizer Bar

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems. Failure of these fasteners

may result in major service expense...

Other information:

Lincoln Aviator 2020-2026 Service Manual: Diagnosis and Testing - Parameter Identification (PID) Chart

Diagnostic PID Chart PID Acronym PID Name Description APP APP sensor APP APP1 APP sensor 1 APP 1 AST Time Since Start Time (in seconds) since the vehicle was started CLRDIST Distance since DTC cleared Distance driven since PCM DTCs were cleared ECT TCM ECT TCM Engine coolant temperature data provided to the TCM ENGLOAD Engine Load Engine load calculated by PCM ETC_ACT Electronic Throttle Control Actual Electronic Throttle Control Actual calculated by PCM FOOT_BRAKE Foot Brake - Foot brake state used by strategy Foot brake state used by strategy calculated by PCM GEAR_CMD Gear Commanded by Module PCM commanded transmission gear GEAR_ENGAGED Transmission Gear Engaged Transmission Gear Engaged GEAR_OSC# Gear Commanded by Output State Control Output state control commanded gear ISS_A_QF Transmission Input Shaft Speed Sensor -A- Quality Factor Transmission Input Shaft Speed Sensor -A- Quality Factor ISS_A_RAW Intermediate Speed -A- Raw Intermediate Speed -A- Raw ISS_B_RAW Intermediate Shaft Speed -B- Raw Intermediate Shaft Speed -B- Raw ISS_B_QF Transmission Input Shaft Speed Sensor -B- Quality Factor Transmission Input Shaft Speed Sensor -B- Quality Factor LINEDSD# Line Pressure Control Desired Commanded line pressure MIL_DIS The distance travelled since the (MIL) was activated The distance travelled since the MIL was activated OSS_QF Transmission Output Shaft Speed Sensor Quality Factor Fault status for the OSS sensor OSS_RAW Output Shaft Speed - Raw Actual speed of the OSS sensor (rpm) PCA Pressure Control Solenoid A LPC PCA AMP# Pressure Control Solenoid A LPC PCA_F Pressure Control Solenoid A Status LPC PWRT_FUNCMON_A Powertrain Secondary Monitor/Performance Fault A Powertrain Secondary Monitor/Performance Fault A PWRT_FUNCMON_B Powertrain Secondary Monitor/Performance Fault A Powertrain Secondary Monitor/Performance Fault A REALTIME Total time (ECU) has been active ECU Time running RPM_TCM Engine Revolutions Per Minute Engine rpm input to TCM SHFT_DROP Shift RPM Drop in Input Shaft Speed Below Expected Shift rpm drop in input shaft speed below expected SHFT_FLRE Shift RPM Rise in Input Shaft Speed Above Expected Shift rpm rise in input shaft speed above expected SHFT_ID Shift Identification of Shift (PID)s Lag, Time, Flare and Drop Shift identification of shift PIDs lag, time, flare and drop SHFT_LAG Shift Time Elapsed From 10% to 90% of Complete Actual time during shift between 10% and 90% complete SHFT_TIME Shift Time Elapsed From Commanded to 10% Complete Shift time 0% to 10% complete SNOWPLW_CFG Snowplow as configured in the (PCM)...

Lincoln Aviator 2020-2026 Owners Manual: Climate

Touch the climate button on the touchscreen to access your climate control features. Note: You can switch temperature units between Fahrenheit and Celsius. Accessing the Climate Control Menu Touch the button to access additional controls for the front climate system...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Child Safety Locks

- Description and Operation - Body and Frame

- Wireless Accessory Charger (If Equipped)

- New on site

- Most important about car

Fastening the Seatbelts

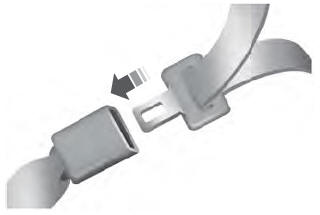

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.