Lincoln Aviator: High Voltage Battery, Mounting and Cables / Description and Operation - High Voltage Battery, Mounting and Cables - Plug-In Hybrid Electric Vehicle (PHEV) - System Operation and Component Description

System Diagram

.jpg)

| Item | Description |

|---|---|

| 1 | Current Sensor |

| 2 | Contactor Sense Leads |

| 3 | BECM |

| 4 | Precharge Contactor Coil |

| 5 | Positive Contactor Coil |

| 6 | Negative Contactor Coil |

| 7 | High Voltage Battery Junction Box |

| 8 | Temperature Sensors |

| 9 | Cell Voltage Sense Leads |

| 10 | PCM |

| 11 | Battery Cell Arrays |

| 12 | GWM |

| 13 | RCM |

| 14 | DCDC |

| 15 | 12 Volt Battery Monitoring Sensor |

| 16 | TCU (if equipped) |

| 17 | Ignition Switch |

| 18 | Main 12 Volt Battery |

| 19 | HVAC |

| 20 | Service Disconnect |

| 21 | High Voltage Battery Coolant Diverter Valve |

| 22 | Motor Electronics Coolant Pump |

| 23 | Isolation Switch (BIB) |

| 24 | Auxiliary 12 Volt Battery |

| 25 | Coolant Temperature Sensor |

| 26 | High Voltage Battery |

| 27 | BCM |

| 28 | High Voltage Battery Coolant Pump |

| 29 | BCMC |

| 30 | SOBDMC |

| 31 | High Voltage Interlock Loop (HVIL) |

| 32 | Auxillary Contactor Coil |

| 33 | SOBDM also known as the Battery Charger Control Module (BCCM) |

System Operation

Network Message Chart - Battery Energy Control Module (BECM)

| Broadcast Message | Originating Module | Message Purpose |

| 12 volt battery voltage | BCM | Battery voltage measured with battery sensor. |

| Accelerator pedal position | PCM | Accelerator pedal position used for OBDII freeze frame data. |

| Charging system fault status messages | SOBDM | Fault status messages of the charger. |

| Charging system status change | SOBDM | Used to communicate when the charger state change is active between not ready, ready, charging, or fault |

| Charger power available change | SOBDM | Used to communicate when the available charger power changed. |

| Plug present cord acknowledgement | SOBDM | Used to communicate if a wall power plug is attached |

| Charger ready status | SOBDM | Used to determine when the charger is ready to charge the high voltage battery. |

| Charger max power input | SOBDM | Maximum power available to the charger from the Electric Vehicle Supply Equipment (EVSE). |

| Charger current output | SOBDM | Measured current output of the charger. |

| Charger high voltage output | SOBDM | Measured high voltage output of the charger. |

| Charger contactor power status | SOBDM | Used to communicate if the contactor power is asserted or not asserted. |

| Plug status event | SOBDM | Used to communicate if the EVSE plug status changes from being plugged in to unplugged from the vehicle charge port. |

| Charger cooling fan request | SOBDM | Used to request the charger cooling fan to Off, Low, Medium, or High |

| SOBDM coolant flow request | SOBDM | Coolant flow request to support cooling of the SOBDM. |

| EVSE power mode | SOBDM | Operational status of the EVSE while it is plugged into the vehicle charge port. |

| Engine coolant temperature | PCM | Engine coolant temperature used for OBDII freeze frame data. |

| Engine load | PCM | Engine calculated load value used for OBDII freeze frame data. |

| Engine RPM | PCM | Engine RPM used for OBDII freeze frame data. |

| Engine warm-up completion status | PCM | Used to increment counters for DTC aging. |

| High voltage battery estimated current flow | SOBDMC | Estimated electric current into or out of the high voltage battery. |

| High voltage battery contactor request | PCM | Command to high voltage battery controller to open, close, or retain the high voltage contactor position. |

| High voltage battery contactor supply voltage status | SOBDMC | Used to determine if the 12V contactor supply voltage is asserted or not asserted. |

| SOBDMC coolant flow request | SOBDMC | Coolant flow request to support cooling of the SOBDMC. |

| High voltage interlock circuit open status | SOBDMC | Notifies the BECM if a high voltage interlock circuit is open which disables the high voltage system. |

| High voltage battery target SOC (State of Charge) percent request | SOBDMC | SOC request for the high voltage battery depending on vehicle drive mode and operating conditions. |

| High voltage battery drive sustain mode | SOBDMC | Used to request high voltage battery drive sustain mode to active or inactive. |

| Cabin drive system mode | SOBDMC | Used to request cabin drive sustain mode to active or inactive. |

| Charge now status | SOBDMC | Used to communicate if the charge now status is active or inactive. |

| Hybrid DC/DC current usage | Direct Current/Direct Current (DC/DC) converter control module | Direct Current/Direct Current (DC/DC) converter control module high voltage current usage for Energy Management (includes all 12V loads). |

| Hybrid DC/DC high voltage measurement | Direct Current/Direct Current (DC/DC) converter control module | Voltage of the high voltage bus as seen by the Direct Current/Direct Current (DC/DC) converter control module. |

| Hybrid DC/DC low voltage measurement | Direct Current/Direct Current (DC/DC) converter control module | Voltage of the low voltage bus as seen by the Direct Current/Direct Current (DC/DC) converter control module. |

| Hybrid DC/DC coolant flow request | Direct Current/Direct Current (DC/DC) converter control module | Coolant flow request to support cooling of the Direct Current/Direct Current (DC/DC) converter control module. |

| Hybrid transaxle inverter voltage | SOBDMC | Voltage on the high voltage cable at the input to the hybrid transaxle. |

| Ignition status | BCM | Current ignition state; off, accessory, run, start, unknown or invalid. |

| Power pack torque status | SOBDMC | Power pack is on or off and if torque is available. |

| Power mode (gateway) | BCM | Information of current power mode state. |

| Restraint impact event status (gateway) | RCM | Used to disable the high voltage system during a crash. |

| Transmission selector (PRNDL) status | PCM | Used to determine transaxle gear state. |

| Vehicle speed | PCM | Vehicle speed data. |

| Odometer master value (gateway) | IPC | Vehicle odometer value. |

| Vehicle configuration data | BCM | Vehicle configuration strategy. |

Cell Balancing

Individual cells can deviate over the life of the high voltage battery. The purpose of cell balancing is to equalize the individual cell charges. By balancing the cells the high voltage battery maintains top efficiency. The BECM continuously monitors individual battery cell voltages and will perform balancing when required and when certain conditions are met. The high voltage battery SOC (State of Charge) must be equal or greater than 15% with the ignition off. The cell balancing will occur for a duration of 24 hours. The ignition key must be cycled for the balancing to start a new 24 hour cell balancing period. When cell balancing is performed BECM discharges individual cells with the highest voltage to match the remaining cells.

Vehicle Shut Down

A vehicle shut down signal is sent by the BECM when the BECM is about to open the contactors due to an internal fault or has just opened the contactors due to an external input (external module commanding contactors to be opened such as a crash event or interlock circuit failure). When vehicle shut down occurs, the Stop Safely warning indicator is illuminated warning that the vehicle will be shut down within a matter of seconds and the operator should pull off the road as soon as possible. Depending on the fault condition that lead to the shutdown, the vehicle may or may not restart if the condition has corrected itself. If the fault condition is severe enough, the fault will have to be repaired and Diagnostic Trouble Codes (DTCs) cleared before the vehicle will restart.

Component Description

High Voltage Battery

The high voltage battery consists of pouch cells packaged into modules which deliver approximately 355 volts DC to the high voltage system. The high voltage battery supplies electrical energy to the electric motor to move the vehicle when it is operating in electric mode only or to assist the Internal Combustion Engine (ICE) (heavy acceleration). When the engine is operating or the vehicle is moving, the electric motor can be used as a generator creating high-voltage AC electricity. High-voltage AC generated by the electric motor is converted to high voltage DC by the SOBDMC and transmitted through the high voltage cables to recharge the high voltage battery.

The high-voltage DC electrical power is converted to low voltage DC electrical power through the Direct Current/Direct Current (DC/DC) converter control module. This low-voltage high current DC electrical power is then supplied to the 12-volt batteries through the low voltage battery cables.

The high-voltage system has a floating ground. The floating ground is designed to completely isolate the high-voltage system from the vehicle chassis. The high-voltage cables are fully insulated (isolated) from all vehicle components and circuits. There are no common connections (such as body grounds) used to conduct the high-voltage power. The BECM monitors this system for any leakage of current to the normal electrical system (similar to a household ground fault interrupter). There are high voltage circuits from the battery cell arrays to the BECM used to monitor isolation resistance between the high voltage battery and chassis.

Battery Energy Control Module (BECM)

The BECM manages the condition of the high voltage battery to control its charging and discharging. The BECM controls the high voltage battery coolant pump in conjunction with BCMC controlling the diverter valve via a HS-CAN request from the SOBDMC. When additional high voltage battery cooling is needed (high ambient temperatures and/or during high current flow demand) the coolant diverter valve is energized to allow coolant to be diverted through the high voltage battery chiller. The high voltage battery chiller is part of the HVAC system used to chill the coolant prior to being returned to the high voltage battery.

The BECM monitors the individual cell voltages and temperature sensors internal to the battery arrays. The BECM monitors the battery current using a sensor located in the high voltage battery junction box. This information is needed by the BECM to control the high voltage battery and determine its ability to receive and provide power to the vehicle. The BECM communicates with other vehicle modules on the HS-CAN.

The BECM receives the following hard-wired inputs:

- HEV (Hybrid Electric Vehicle) wakeup

- High voltage battery connector interlock status

- High voltage battery contactor control supply voltage (includes the service disconnect)

- High voltage battery cells sense leads

- High voltage battery cell temperature sensors

- High voltage battery coolant inlet temperature sensor

- High voltage battery coolant pump feedback signal

- Motor electronics coolant pump feedback signal

- Current sensor (part of the high voltage battery junction box)

- Event notification status from the RCM

- HS-CAN

The BECM provides the following outputs:

- High voltage battery coolant pump PWM control signal

- Motor electronics coolant pump PWM control signal

- High voltage battery junction box pre-charge contactor control

- High voltage battery junction box positive contactor control

- High voltage battery junction box negative contactor control

- High voltage battery junction box auxiliary contactor control

- HEV (Hybrid Electric Vehicle) wakeup

- HS-CAN information

Direct Current/Direct Current (DC/DC) Converter Control Module

The DCDC is an liquid-cooled component that converts high voltage (192-413 volts) DC power to low-voltage (12 volt) DC power. The converter provides power to the vehicle 12-volt battery and low-voltage electrical systems. The PCM

requests the Direct Current/Direct Current (DC/DC) converter control

module to enable power conversion through an enable message over HS-CAN. The PCM sends a charging voltage setpoint request over HS-CAN to the Direct Current/Direct Current (DC/DC) converter control module. For information on the DCDC,

Refer to: Direct Current/Direct Current (DC/DC) Converter Control Module - System Operation and Component Description (414-05 Voltage Converter/Inverter, Description and Operation).

Hybrid Electric Motor Assembly

The hybrid electric motor assembly is mounted to the front of the transmission assembly and is also used as a generator. The assembly also incorporates an electric operated engine disconnect clutch that engages or disengages the electric motor from the Internal Combustion Engine (ICE).

The electric motor generates high voltage electricity for charging the high voltage battery. The engine is started using either conventional engine block mounted starter (for cold starts only) and a Belt Integrated Starter Generator (BISG) for other starts during normal vehicle operation. The electric motor must be energized and rotated to match Internal Combustion Engine (ICE) cranking speed during starting. If the high voltage system is shutdown due to a malfunction the Internal Combustion Engine (ICE) will not start and the vehicle will be disabled.

The

electric motor is used to accelerate the vehicle from a stop when

driving under electric power. The electric motor is also used to recover

energy during regenerative braking. The electric motor receives power

from the high voltage battery after the high voltage battery junction

box contactors have closed. For information on the electric motor and

its operation,

Refer to: Electric Motor (303-01C Electric Motor, Description and Operation).

During

braking and deceleration events the regenerative brake system utilizes

the electric motor as a generator to create and capture electrical

current. This captured energy is used to charge the high voltage

battery. If the high voltage battery is adequately charged, the captured

energy is used for Internal Combustion Engine (ICE) braking to slow the

vehicle. The regenerative brake system is a series system which the

generator braking is used first, up to the limits of the generator

torque capacity and the high voltage battery charging capacity. After

optimum regeneration is used, the friction brakes are applied to

supplement braking demands. For information on regenerative braking,

Refer to: Anti-Lock Brake System (ABS) and Stability Control - System Operation and Component Description (206-09 Anti-Lock Brake System (ABS) and Stability Control, Description and Operation).

High Voltage Battery Junction Box

The high voltage battery junction box houses the 4 contactors (precharge, main positive, main negative, and auxiliary negative) which, when commanded closed by the BECM, connect the high voltage battery to various components for high-voltage consumption and/or charging of the high voltage battery. During initial power up after the negative contactors (main negative and auxiliary negative) are closed, the precharge contactor closes prior to the positive contactor which routes high voltage through the precharge resistor which is also located in the high voltage battery junction box. This reduces the in rush current to prevent contactor damage. The high voltage battery junction box design distributes high-voltage via three circuits to various high voltage components. The high voltage battery has three high voltage negative outputs and shared high voltage positive output. The single high voltage high current circuit supplies the negative polarity to the SOBDMC also known as the Inverter System Controller (ISC) and is protected by a high voltage 300A fuse. One high voltage low current circuit supplies the negative polarity to the DCDC and SOBDM also known as the Battery Charger Control Module (BCCM) and is protected by a high-voltage 40A fuse and a separate high voltage low current circuit supplies negative polarity to the Cabin Coolant Heater and ACCM and is protected by a second high-voltage 40A fuse. The high current positive side is shared with all the high voltage components. Any fault resulting in excessive current on a low current circuit will open the affected 40A fuse first and stop power distribution to the components on that circuit. Any fault resulting in excessive current on the high current circuit will open the 300A fuse and stop power distribution to the SOBDMC. Note the high voltage fuse current ratings reference the operating current of the circuit and not the faulted current to open the high voltage fuse. The high voltage battery junction box contains the contactors, the current sensor, high-voltage high current 300A fuse, and two high-voltage low current 40A fuses.

The high voltage battery junction box contains a current sensor that is hardwired to and monitored by the BECM. The current sensor helps determine the load or rate of charge of the high voltage battery by sensing current flow into or out of the high voltage battery. The high voltage battery junction box also contains voltage sense points downstream of the high voltage contactors that are used to detect issues with the contactors.

High Voltage Cable Assembly

All cables that carry high voltage are integrated into two high-voltage cable assemblies. The primary high-voltage cable connects the high voltage battery, SOBDMC, DCDC, SOBDM and the cabin coolant heater. Another high voltage cable connects the ACCM to the primary high voltage battery cable. There are 4 circuits that connect to the High Voltage Battery. Two main circuits supply high voltage to the SOBDMC. Two separate high voltage low current circuits supply negative polarity to the DCDC and the Cabin Coolant Heater. The DCDC acts as a junction and sends high voltage to the SOBDM and the Cabin Coolant Heater acts as a junction for the other low current circuit and sends high voltage to the ACCM. There is a separate 3 phase AC high voltage cable assembly that connects the hybrid electric motor assembly and the SOBDMC.

High Voltage System Service Disconnect Plug

The

high voltage system uses a low voltage disconnect plug that opens the

12-Volt contactor control supply circuit and is located in the engine

compartment. When the service disconnect plug is disconnected the high

voltage battery contactors that supply high voltage to the vehicle are

unable to close. The high voltage system must be depowered prior to

disconnecting any high voltage cable (identified by orange color).

Refer to: High Voltage System De-energizing (414-03A High Voltage Battery, Mounting and Cables, General Procedures).

Description and Operation - High Voltage Battery, Mounting and Cables - Plug-In Hybrid Electric Vehicle (PHEV) - Overview

Description and Operation - High Voltage Battery, Mounting and Cables - Plug-In Hybrid Electric Vehicle (PHEV) - Overview

OVERVIEW

WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system...

Other information:

Lincoln Aviator 2020-2024 Owners Manual: Washer Fluid Check. Fuel Filter. Checking the Wiper Blades

Washer Fluid Check WARNING: If you operate your vehicle in temperatures below 41.0°F (5°C), use washer fluid with antifreeze protection. Failure to use washer fluid with antifreeze protection in cold weather could result in impaired windshield vision and increase the risk of injury or accident...

Lincoln Aviator 2020-2024 Service Manual: Description and Operation - Vehicle Dynamic Suspension - Vehicles With: Air Suspension - System Operation and Component Description

System Operation System Diagram Item Description 1 HS-CAN2 2 HS-CAN1 3 HS-CAN3 4 SUMA and Air Compressor Assembly 5 LHF Air Spring Solenoid 6 PSCM 7 PCM 8 ABS 9 LHF Height Sensor 10 RHF Height Sensor 11 LHR Height Sensor 12 RHR Height Sensor 13 BCM 14 RHF Air Spring Solenoid 15 LHR Air Spring Solenoid 16 RHR Air Spring Solenoid 17 IPC 18 RCM 19 GWM Network Message Chart Module Network Input Messages - SUMA Broadcast Message Originating Module Message Purpose ABS active ABS module Indicates the current ABS activity, on or off...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Resetting the System

- Body and Paint

- Tire Change Procedure

- New on site

- Most important about car

Fastening the Seatbelts

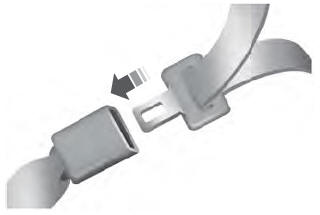

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

.jpg)