Lincoln Aviator: Parking Brake and Actuation / Diagnosis and Testing - Parking Brake

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| ABS | B1111:4B | Electric Park Brake Enable:Over Temperature | GO to Pinpoint Test F |

| ABS | B1111:53 | Electric Park Brake Enable:Deactivated | GO to Pinpoint Test G |

| ABS | B1111:54 | Electric Park Brake Enable:Missing Calibration | GO to Pinpoint Test E |

| ABS | C0609:01 | Park Brake Switch Circuit:General Electrical Failure | GO to Pinpoint Test B |

| ABS | C0616:9A | Park Brake Control Module Control Circuit Performance:Component or System Operating Conditions | GO to Pinpoint Test B |

| ABS | C1034:01 | Park Brake:General Electrical Failure | GO to Pinpoint Test B |

| ABS | C1034:07 | Park Brake:Mechanical Failures | GO to Pinpoint Test K |

| ABS | C1034:13 | Park Brake:Circuit Open | GO to Pinpoint Test B |

| ABS | C1034:25 | Park Brake:Signal Shape/Waveform Failure | GO to Pinpoint Test B |

| ABS | C1034:2F | Park Brake:Signal Erratic | GO to Pinpoint Test B |

| ABS | C1034:47 | Park Brake:Watchdog/Safety µC Failure | GO to Pinpoint Test B |

| ABS | C1034:48 | Park Brake:Supervision Software Failure | GO to Pinpoint Test B |

| ABS | C1034:57 | Park Brake:Invalid/Incompatible Software Component | GO to Pinpoint Test B |

| ABS | C1034:71 | Park Brake:Actuator Stuck | GO to Pinpoint Test C |

| ABS | C1034:77 | Park Brake:Commanded Position Not Reachable | GO to Pinpoint Test C |

| ABS | C1034:78 | Park Brake:Alignment Or Adjustment Incorrect | GO to Pinpoint Test H |

| ABS | C1034:97 | Park Brake:Component or System Operation Obstructed or Blocked | GO to Pinpoint Test D |

| ABS | C1A43:98 | Motor Supply:Component or System Over Temperature | GO to Pinpoint Test D |

| ABS | C2005:18 | Right Actuator:Circuit Current Below Threshold | GO to Pinpoint Test D |

| ABS | C2005:19 | Right Actuator:Circuit Current Above Threshold | GO to Pinpoint Test D |

| ABS | C2005:77 | Right Actuator:Commanded Position Not Reachable | GO to Pinpoint Test C |

| ABS | C2005:78 | Right Actuator:Alignment Or Adjustment Incorrect | GO to Pinpoint Test A |

| ABS | C2006:18 | Left Actuator:Circuit Current Below Threshold | GO to Pinpoint Test D |

| ABS | C2006:19 | Left Actuator:Circuit Current Above Threshold | GO to Pinpoint Test D |

| ABS | C2006:77 | Left Actuator:Commanded Position Not Reachable | GO to Pinpoint Test C |

| ABS | C2006:78 | Left Actuator:Alignment Or Adjustment Incorrect | GO to Pinpoint Test A |

| ABS | C2007:13 | Right Motor:Circuit Open | GO to Pinpoint Test D |

| ABS | C2007:1C | Right Motor:Circuit Voltage Out Of Range | GO to Pinpoint Test D |

| ABS | C2007:92 | Right Motor:Performance Or Incorrect Operation | GO to Pinpoint Test D |

| ABS | C2008:13 | Left Motor:Circuit Open | GO to Pinpoint Test D |

| ABS | C2008:1C | Left Motor:Circuit Voltage Out Of Range | GO to Pinpoint Test D |

| ABS | C2008:92 | Left Motor:Performance Or Incorrect Operation | GO to Pinpoint Test D |

| ABS | U2002:00 | Switch:No Sub Type Information | GO to Pinpoint Test J |

| ABS | U2002:47 | Switch:Watchdog/Safety µC Failure | GO to Pinpoint Test B |

Symptom Chart(s)

Symptom Chart: Parking Brake and Actuation

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

| Condition | Possible Sources | Actions |

|---|---|---|

| A module does not respond to the diagnostic scan tool |

|

REFER to: Communications Network (418-00 Module Communications Network, Diagnosis and Testing). |

| The yellow parking brake indicator is always or never on |

|

GO to Pinpoint Test I |

| Message center displays Park Brake Malfunction Service Now |

|

GO to Pinpoint Test I |

| Message center displays Park Brake Limited Function Service Required | Diagnostic Trouble Codes (DTCs) present in the ABS module | GO to Pinpoint Test I |

| Message center displays Maintenance Mode | Parking brake system is in maintenance mode (service mode) | GO to Pinpoint Test I |

| Rear brakes drag | Refer to the Pinpoint Test | GO to Pinpoint Test D |

| The parking brake does not apply or does not hold the vehicle | Refer to the Pinpoint Test | GO to Pinpoint Test D |

| The parking brake does not release using the park brake switch | Refer to the Pinpoint Test | GO to Pinpoint Test B |

| The parking brake automatic release function does not operate | Refer to the Pinpoint Test | GO to Pinpoint Test D |

Pinpoint Tests

.jpg) PINPOINT TEST A : C2005:78, C2006:78

PINPOINT TEST A : C2005:78, C2006:78|

Refer to Wiring Diagrams Cell 42 for schematic and connector information. Normal Operation and Fault Conditions The ABS module measures the current draw of both actuator motors during each parking brake apply request. Current draw measurement for these 2 Diagnostic Trouble Codes (DTCs) starts when the caliper piston and brake pad start moving and stops when the brake pad contacts the brake disc, this is known as free run. If the free run current draw exceeds the programmed limit, the ABS module sets a DTC. This is most likely caused by high mechanical resistance in the actuator or motor, a shorted motor, a blocked motor or a seized motor.

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||

| A1 CHECK FOR OTHER ABS (ANTI-LOCK BRAKE SYSTEM) MODULE DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||

Are there additional Diagnostic Trouble Codes (DTCs) set in the ABS module?

|

|||||||||

| A2 USING THE DIAGNOSTIC SCAN TOOL | |||||||||

Are there additional Diagnostic Trouble Codes (DTCs) set in the ABS module again?

|

|||||||||

| A3 CARRY OUT THE APPLY AND RELEASE ROUTINE | |||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST B : THE PARKING BRAKE DOES NOT OPERATE CORRECTLY OR THE PARKING BRAKE DOES NOT RELEASE USING THE PARK BRAKE SWITCH

PINPOINT TEST B : THE PARKING BRAKE DOES NOT OPERATE CORRECTLY OR THE PARKING BRAKE DOES NOT RELEASE USING THE PARK BRAKE SWITCH|

Refer to Wiring Diagrams Cell 42 for schematic and connector information. Normal Operation and Fault Conditions The parking brake switch has 3 positions; APPLY (pulled up), RELEASE (pushed down) and NEUTRAL. The ABS module sends voltage to the parking brake switch and this voltage returns along 1 of 3 circuits. An open, excessive resistance or a short in the parking brake switch circuits or the parking brake switch causes the ABS module to set a DTC.

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B1 TEST THE PARKING BRAKE SWITCH IN THE APPLIED POSITION | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 5 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B2 TEST THE PARKING BRAKE SWITCH IN THE RELEASED POSITION | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 5 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B3 CHECK THE PARKING BRAKE SWITCH CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NOTE: Performing this step sets Diagnostic Trouble Codes (DTCs) in the ABS module.

Is any voltage present?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B4 CHECK THE PARKING BRAKE SWITCH CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B5 CHECK THE PARKING BRAKE SWITCH CIRCUITS FOR AN OPEN | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances less than 3 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B6 CHECK THE PARKING BRAKE SWITCH CIRCUITS FOR A SHORT TOGETHER | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B7 VERIFY ALL WIRING CONNECTIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Are the connectors free of corrosion, damaged pins, bent pins, pushed-out pins and spread terminals?

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| B8 CHECK FOR CORRECT ABS (ANTI-LOCK BRAKE SYSTEM) MODULE OPERATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST C : C1034:71, C1034:77, C2005:77, C2006:77

PINPOINT TEST C : C1034:71, C1034:77, C2005:77, C2006:77|

Refer to Wiring Diagrams Cell 42 for schematic and connector information. Normal Operation and Fault Conditions When the ABS module receives a parking brake apply or release request, the ABS module sends voltage to the parking brake actuator motors. The ABS module also monitors the current draw of the actuator motors to determine when the brake pads contact the brake disc, to determine when the appropriate amount of clamping force is being applied to the brake disc and to determine when the brake pads are retracted to their start position. The actuator motors have a serviceable jumper harness connecting the actuator motor to the body harness at C334 for the LH actuator motor and C316 for the RH actuator motor.

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||||||||||||||||||

| C1 CHECK FOR OTHER ABS (ANTI-LOCK BRAKE SYSTEM) MODULE DIAGNOSTIC TROUBLE CODES (DTCS) | ||||||||||||||||||||||

Is DTC C1034:77, C2005:78 or C2006:78 present?

|

||||||||||||||||||||||

| C2 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TO VOLTAGE | ||||||||||||||||||||||

|

NOTE: Performing this step sets Diagnostic Trouble Codes (DTCs) in the ABS module.

Is any voltage present?

|

||||||||||||||||||||||

| C3 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TO GROUND | ||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

||||||||||||||||||||||

| C4 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TOGETHER | ||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

||||||||||||||||||||||

| C5 CHECK THE ACTUATOR MOTOR CIRCUITS FOR HIGH RESISTANCE AND AN OPEN | ||||||||||||||||||||||

|

NOTE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may cause damage to the connector. NOTE: This step puts a load on the actuator motor circuits. If there are corroded or loose connections, loading the circuit(s) may help show the fault. A 3157 headlamp bulb would be an effective load.

Is the voltage drop less than 0.5 volt?

|

||||||||||||||||||||||

| C6 INSPECT THE ACTUATOR MOTOR FOR EVIDENCE OF BRAKE FLUID OR WATER INTRUSION | ||||||||||||||||||||||

Is there any evidence of brake fluid leaks or water intrusion?

|

||||||||||||||||||||||

| C7 INSPECT THE BRAKE CALIPER FOR BRAKE FLUID LEAKS | ||||||||||||||||||||||

Are there any signs of brake fluid leaks?

|

||||||||||||||||||||||

| C8 INSPECT THE BRAKE CALIPER HARDWARE | ||||||||||||||||||||||

Are there any concerns with hardware?

|

.jpg) PINPOINT

TEST D : THE PARKING BRAKE DOES NOT HOLD THE VEHICLE, DOES NOT APPLY,

DOES NOT RELEASE USING THE AUTOMATIC RELEASE FUNCTION

PINPOINT

TEST D : THE PARKING BRAKE DOES NOT HOLD THE VEHICLE, DOES NOT APPLY,

DOES NOT RELEASE USING THE AUTOMATIC RELEASE FUNCTION|

Refer to Wiring Diagrams Cell 42 for schematic and connector information. Normal Operation and Fault Conditions When the ABS module receives a parking brake apply or release request, the ABS module sends voltage to the parking brake actuator motors. The ABS module also monitors the current draw of the actuator motors to determine when the brake pads contact the brake disc, to determine when the appropriate amount of clamping force is being applied to the brake disc and to determine when the brake pads are retracted to their start position. A HS-CAN issue or concern results in a failure to release the parking brake. The ABS module runs self-tests before, during and after an apply or release request. These self-tests are done to determine parking brake system functionality. High actuator motor circuit resistance, a short to ground, a short to voltage, an open circuit, a mechanical or electrical failure of the actuator motor or an internal failure of the ABS module may cause one or more of these self-tests to fail resulting in the ABS module setting one or more Diagnostic Trouble Codes (DTCs). The actuator motors have a serviceable jumper harness connecting the actuator motor to the body harness at C334 for the LH actuator motor and C316 for the RH actuator motor.

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

|||||||||||||||||||||||||||||||||||||||

| D1 CHECK FOR ABS (ANTI-LOCK BRAKE SYSTEM) MODULE DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||

|

NOTE: A HS-CAN issue or concern results in a failure to release the parking brake.

Are any of the Diagnostic Trouble Codes (DTCs) listed in the DTC Fault Trigger Conditions table present in the ABS module?

|

|||||||||||||||||||||||||||||||||||||||

| D2 VERIFY AUTOMATIC RELEASE FUNCTIONALITY | |||||||||||||||||||||||||||||||||||||||

Does the parking brake automatically release when the accelerator pedal is pressed?

|

|||||||||||||||||||||||||||||||||||||||

| D3 CHECK THE BCM (BODY CONTROL MODULE) AND PCM (POWERTRAIN CONTROL MODULE) FOR DIAGNOSTIC TROUBLE CODES (DTCS) | |||||||||||||||||||||||||||||||||||||||

Are any Diagnostic Trouble Codes present in the BCM or PCM?

|

|||||||||||||||||||||||||||||||||||||||

| D4 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TO VOLTAGE | |||||||||||||||||||||||||||||||||||||||

|

NOTE: Performing this step sets Diagnostic Trouble Codes (DTCs) in the ABS module.

Is any voltage present?

|

|||||||||||||||||||||||||||||||||||||||

| D5 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TO GROUND | |||||||||||||||||||||||||||||||||||||||

Are the resistances greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||

| D6 CHECK THE ACTUATOR MOTOR CIRCUITS FOR A SHORT TOGETHER | |||||||||||||||||||||||||||||||||||||||

Is the resistance greater than 10,000 ohms?

|

|||||||||||||||||||||||||||||||||||||||

| D7 CHECK THE ACTUATOR MOTOR CIRCUITS FOR HIGH RESISTANCE AND AN OPEN | |||||||||||||||||||||||||||||||||||||||

|

NOTE: Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may cause damage to the connector. NOTE: This step puts a load on the actuator motor circuits. If there are corroded or loose connections, loading the circuit(s) may help show the fault. A 3157 headlamp bulb would be an effective load.

Is the voltage drop less than 0.5 volt?

|

|||||||||||||||||||||||||||||||||||||||

| D8 CHECK THE ACTUATOR MOTOR RESISTANCE | |||||||||||||||||||||||||||||||||||||||

Is the resistance less than 500 ohms?

|

|||||||||||||||||||||||||||||||||||||||

| D9 CHECK THE BRAKE CALIPER BALL SCREW DRIVE | |||||||||||||||||||||||||||||||||||||||

Does the ball screw drive turn with less than 5 Nm (44 lb-in) or turning force?

|

|||||||||||||||||||||||||||||||||||||||

| D10 VERIFY ALL WIRING CONNECTIONS | |||||||||||||||||||||||||||||||||||||||

Are the connectors free of corrosion, damaged pins, bent pins, pushed-out pins and spread terminals?

|

|||||||||||||||||||||||||||||||||||||||

| D11 CHECK FOR CORRECT ABS (ANTI-LOCK BRAKE SYSTEM) MODULE OPERATION | |||||||||||||||||||||||||||||||||||||||

Is the concern still present?

|

.jpg) PINPOINT TEST E : B1111:54

PINPOINT TEST E : B1111:54|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| E1 CHECK VEHICLE HISTORY | ||||||

Were there any recent ABS service actions?

|

||||||

| E2 CARRY OUT THE ABS SELF TEST | ||||||

Did other ABS module Diagnostic Trouble Codes (DTCs) set?

|

||||||

| E3 CARRY OUT THE EPB INITIALIZATION ROUTINE | ||||||

Is DTC B1111:54 present?

|

||||||

| E4 PERFORM THE PMI PROCEDURE FOR ABS | ||||||

Is DTC B1111:54 present?

|

.jpg) PINPOINT TEST F : B1111:4B

PINPOINT TEST F : B1111:4B|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| F1 CARRY OUT THE EPB APPLY AND RELEASE ROUTINE | ||||||

Is DTC B1111:4B set?

|

.jpg) PINPOINT TEST G : B1111:53

PINPOINT TEST G : B1111:53|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| G1 CARRY OUT THE EPB APPLY AND RELEASE ROUTINE | ||||||

Is DTC B1111:53 set?

|

.jpg) PINPOINT TEST H : C1034:78

PINPOINT TEST H : C1034:78|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| H1 CARRY OUT THE ABS SELF TEST | ||||||

Is DTC C1034:78 set?

|

.jpg) PINPOINT TEST I : THE MESSAGE CENTER DISPLAYS PARK BRAKE RELATED MESSAGES

PINPOINT TEST I : THE MESSAGE CENTER DISPLAYS PARK BRAKE RELATED MESSAGES|

Possible Sources

|

||||

| I1 CARRY OUT THE ABS SELF-TEST | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

||||

| I2 CARRY OUT THE EPB APPLY AND RELEASE ROUTINE | ||||

Are any Diagnostic Trouble Codes (DTCs) present?

|

.jpg) PINPOINT TEST J : U2002:00

PINPOINT TEST J : U2002:00|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources |

||||||

| J1 CARRY OUT THE ABS SELF TEST | ||||||

Is DTC U2002:00 set?

|

.jpg) PINPOINT TEST K : C1034:07

PINPOINT TEST K : C1034:07|

Normal Operation and Fault Conditions

REFER to: Parking Brake - System Operation and Component Description (206-05 Parking Brake and Actuation, Description and Operation). DTC Fault Trigger Conditions

Possible Sources

|

||||||

| K1 CHECK THE REAR BRAKE PADS | ||||||

Are the brake pads present and do the brake pads meet the minimum thickness specification?

|

||||||

| K2 CHECK THE REAR BRAKE DISCS | ||||||

Do the brake discs meet the minimum thickness specification?

|

||||||

| K3 CHECK THE ACTUATOR PISTON OPERATION | ||||||

Does the piston move when the ball screw drive is turned?

|

Description and Operation - Parking Brake - System Operation and Component Description

Description and Operation - Parking Brake - System Operation and Component Description

System Operation

System Diagram

E338887

*.sttxt {

visibility: hidden;

}

*.stcallout {

visibility: visible;

}

1

Parking Brake

Control Switch

2

LH Parking Brake

Actuator Motor

3

RH Parking Brake

Actuator Motor

4

PCM

5

GSM

6

RCM

7

BCM

8

GWM

9

IPC

10

ABS

HS-CAN 2

HS-CAN 1

FD-CAN

HS-CAN 3

Item

Description

1

Parking Brake Control Switch

2

LH Parking Brake Actuator Motor

3

RH Parking Brake Actuator Motor

4

PCM

5

GSM

6

RCM

7

BCM

8

GWM

9

IPC

10

ABS

Network Message Chart

ABS Module Electronic Parking Brake Network Input Messages

Broadcast Message

Originating Module

Message Purpose

Accelerator pedal position

PCM

This message is sent to the GWM and then to the ABS module...

Removal and Installation - Parking Brake Actuator Motor

Removal and Installation - Parking Brake Actuator Motor

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

LH side shown, RH similar.

With the vehicle in NEUTRAL, position it on a hoist...

Other information:

Lincoln Aviator 2020-2026 Owners Manual: General Information

Condensation in the Exterior Front Lamps and Rear Lamps Exterior front lamps and rear lamps have vents to accommodate normal changes in air pressure. Condensation can be a natural by-product of this design. When moist air enters the lamp assembly through the vents, there is a possibility that condensation can occur when the temperature is cold...

Lincoln Aviator 2020-2026 Service Manual: Specifications

General Specifications Item Specification Normal engine cranking speed (Average) 140-200 RPM Starting circuit maximum voltage drop (Engine at normal operating temperature) (Average) 0...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Resetting the System

- Anti-Theft Alarm

- Remove and Reinstall the Battery

- New on site

- Most important about car

Fastening the Seatbelts

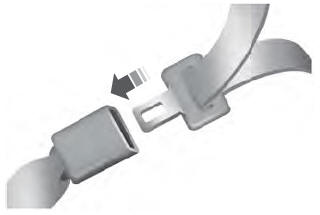

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

.jpg) PINPOINT TEST A : C2005:78, C2006:78

PINPOINT TEST A : C2005:78, C2006:78.jpg)

.jpg)