Lincoln Aviator 2020-2026 Service Manual / Chassis / Driveline / Driveshaft / General Procedures - Driveshaft Angle Measurement

Lincoln Aviator: Driveshaft / General Procedures - Driveshaft Angle Measurement

Check

NOTE: Prior to checking driveline angularity, inspect the U-joints for correct operation.

NOTE: An incorrect driveline angle can cause a vibration or shudder.

NOTE: Driveline angularity is the angular relationship between the engine crankshaft, the driveshaft and the rear axle pinion. Factors determining driveline angularity include ride height, rear spring and engine mounts.

All vehicles

-

Carry out the following preliminary setup steps:

-

Inspect the U-joints for correct operation.

-

Park the vehicle on a level surface such as a drive-on hoist, or back onto a front end alignment rack.

-

Inspect the U-joints for correct operation.

Vehicles with flex coupling, CV joints

-

Calibrate the anglemaster by placing it on the

bottom of the transmission fluid pan and press the ALT-ZERO button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

Measure the slope of the front tube of the rear

driveshaft. The measured angle will be the front joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

Calibrate the anglemaster by placing it on the

clean, flat surface of the rear driveshaft front tube and press the

ALT-ZERO button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

Measure the slope of the rear tube of the rear

driveshaft. The measured angle will be the center joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

Calibrate the anglemaster by placing it on the

clean, flat locator surface on the right side of the drive axle and

press the ALT-ZERO button.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

Measure the slope of the rear tube of the rear

driveshaft. The measured angle will be the rear joint operating angle.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

-

Special Tool(s): Anglemaster II Driveline Inclinometer/Protractor 164-R2402.

.jpg) |

-

If the angle is not within specifications, repair or

adjust to obtain the correct angle. Inspect the engine mounts,

transmission mounts, transfer case mounts, center support bearing

mounting, rear subframe, rear axle, rear axle mounting or the frame for

wear or damage.

4x4 Vehicles with front driveshafts

-

Front driveshaft joint angle is set from the factory and is not adjustable.

Diagnosis and Testing - Driveshaft

Diagnosis and Testing - Driveshaft

Preliminary Inspection

Visually inspect the CV joints for obvious signs of mechanical damage.

If an obvious cause for an observed or reported concern is

found, correct the cause (if possible) before proceeding to the next

step

If the cause is not visually evident, verify the symptom and REFER to Symptom Chart: NVH...

General Procedures - Driveshaft Runout and Balancing

General Procedures - Driveshaft Runout and Balancing

Special Tool(s) /

General Equipment

100-002

(TOOL-4201-C)

Holding Fixture with Dial Indicator Gauge

Inspection

NOTE:

Driveline vibration exhibits a higher frequency and lower

amplitude then high-speed shake...

Other information:

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Front Seat Backrest Cover - Vehicles With: Multi-Contour Seats

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: Driver seat shown, passenger seat similar. Remove the front seat. Refer to: Front Seat (501-10A Front Seats, Removal and Installation). Remove the front seat backrest panel...

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Rear Door Lock Control Switch

Special Tool(s) / General Equipment Interior Trim Remover Removal NOTE: LH (left-hand) side shown, RH (right-hand) side similar. Remove the rear door window control switch bezel assembly. Release the locking tabs from the rear door window control switch bezel assembly...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Interior Lamps

- Fuel Quality

- Child Safety Locks

- New on site

- Most important about car

Fastening the Seatbelts

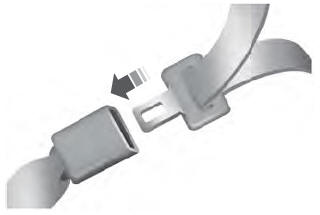

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2026 www.liaviator2.com