Lincoln Aviator 2020-2026 Service Manual / Chassis / Driveline / Front Drive Axle/Differential / Removal and Installation - Axle Assembly

Lincoln Aviator: Front Drive Axle/Differential / Removal and Installation - Axle Assembly

Removal

-

Remove the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

-

Drain the front differential fluid.

Refer to: Differential Draining and Filling (205-03 Front Drive Axle/Differential, General Procedures).

-

Remove the front RH halfshaft only.

Refer to: Halfshaft (205-04 Front Drive Halfshafts, Removal and Installation).

-

Remove the engine mount RH.

Refer to: Engine Mount RH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

-

Disconnect the front drive axle speed sensor electrical connector and position the wiring harness aside.

.jpg) |

-

Disconnect the tie strap, detach and position the front axle breather hose aside.

.jpg) |

-

-

Remove and discard the front axle assembly bolts.

-

Remove the front axle assembly.

-

Remove and discard the front axle assembly bolts.

.jpg) |

-

Remove and discard the O-ring.

.jpg) |

Installation

-

NOTE: Make sure that the surface is clean and free of foreign material.

Clean and inspect the O-ring mating surface.

.jpg) |

-

NOTE: Make sure that a new O-ring seal is installed.

Install a new O-ring.

.jpg) |

-

NOTE: Make sure that the mating surface and the bore is free of corrosion and foreign material, avoid particles getting into the bore.

Clean and inspect the engine oil pan at front axle assembly mating surface.

.jpg) |

-

Install the front axle assembly and the new bolts.

Torque: 66 lb.ft (90 Nm)

.jpg) |

-

Attach the front axle breather hose and the tie strap.

.jpg) |

-

Connect the front drive axle speed sensor electrical

connector and position the wiring harness with proper routing.

.jpg) |

-

Install the engine mount RH.

Refer to: Engine Mount RH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

-

Install the front driveshaft.

Refer to: Front Driveshaft (205-01 Driveshaft, Removal and Installation).

-

Install the front RH halfshaft.

Refer to: Halfshaft (205-04 Front Drive Halfshafts, Removal and Installation).

-

Fill the front differential with clean fluid.

Refer to: Differential Draining and Filling (205-03 Front Drive Axle/Differential, General Procedures).

General Procedures - Differential Fluid Level Check

General Procedures - Differential Fluid Level Check

Materials

Name

Specification

Motorcraft® SAE 75W-140 Synthetic Rear Axle LubricantXY-75W140-QL

WSL-M2C192-A

Check

With the vehicle in NEUTRAL, position it on a hoist...

Removal and Installation - Axle Shaft Seal

Removal and Installation - Axle Shaft Seal

Special Tool(s) /

General Equipment

205-907Handle, 32 DriverTKIT-2008DH-FLM

307-256

(T92P-77000-FH)

Installer, Differential Fluid SealTKIT-1992-FLMH/LMH

Removal

NOTE:

The stub shaft seals must be replaced whenever the halfshafts are removed...

Other information:

Lincoln Aviator 2020-2026 Owners Manual: Principle of Operation

WARNING: Airbags do not inflate slowly or gently, and the risk of injury from a deploying airbag is the greatest close to the trim covering the airbag module. WARNING: All occupants of your vehicle, including the driver, should always properly wear their seatbelts, even when an airbag supplemental restraint system is provided...

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Headliner - Lowering

Special Tool(s) / General Equipment Pick Hook Interior Trim Remover Remove the following items: On both sides. Remove the A-pillar trim panel. Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation)...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Resetting the System

- Child Safety Locks

- Description and Operation - Body and Frame

- New on site

- Most important about car

Fastening the Seatbelts

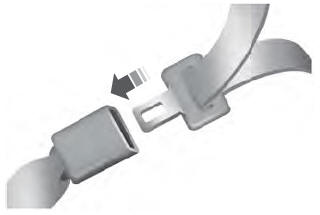

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2026 www.liaviator2.com