Lincoln Aviator: High Voltage Battery, Mounting and Cables / Removal and Installation - High Voltage Battery Cables - Plug-In Hybrid Electric Vehicle (PHEV)

Removal

.jpg) WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system. The high-voltage system utilizes approximately

450 volts DC, provided through high-voltage cables to its components and

modules. The high-voltage cables and wiring are identified by orange

harness tape or orange wire covering. All high-voltage components are

marked with high-voltage warning labels with a high-voltage symbol.

Failure to follow these instructions may result in serious personal

injury or death.

WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system. The high-voltage system utilizes approximately

450 volts DC, provided through high-voltage cables to its components and

modules. The high-voltage cables and wiring are identified by orange

harness tape or orange wire covering. All high-voltage components are

marked with high-voltage warning labels with a high-voltage symbol.

Failure to follow these instructions may result in serious personal

injury or death.

-

.jpg) WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Position vehicle on the hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

De-energize the high voltage system.

Refer to: High Voltage System De-energizing (414-03A High Voltage Battery, Mounting and Cables, General Procedures).

-

Disconnect the battery negative terminal.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

Remove the bolts and the suspension support bar.

Torque:

22 lb.ft (30 Nm)

High Voltage Battery Cable

-

Remove the cowl panel.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

-

Remove the push pins.

-

Remove the fasteners.

-

Remove the stamp nuts.

-

Remove the nuts.

Torque:

53 lb.in (6 Nm)

-

-

Remove the nuts.

Torque:

53 lb.in (6 Nm)

-

Remove the screws.

Torque:

27 lb.in (3 Nm)

-

Remove the fasteners.

-

-

Remove the bolts.

Torque:

97 lb.in (11 Nm)

-

Remove the nuts and the RH floor heat shield.

Torque:

97 lb.in (11 Nm)

-

Remove the RH catalytic converter.

Refer to: Catalytic Converter RH - Plug-In Hybrid Electric Vehicle (PHEV) (309-00B Exhaust System - 3.0L EcoBoost – Hybrid (BQ), Removal and Installation).

Refer to: Catalytic Converter RH - Plug-In Hybrid Electric Vehicle (PHEV) (309-00B Exhaust System - 3.0L EcoBoost – Hybrid (BQ), Removal and Installation).

-

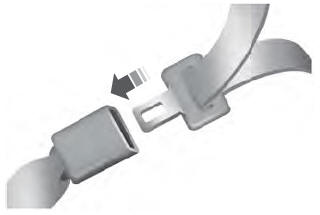

Disconnect the high voltage battery cable electrical connector.

-

Remove the nuts and position aside the wire harness.

Torque:

53 lb.in (6 Nm)

-

Remove the nuts and position aside the wire harness.

Torque:

53 lb.in (6 Nm)

-

-

Remove the nut.

Torque:

97 lb.in (11 Nm)

-

Remove the screw.

Torque:

97 lb.in (11 Nm)

-

Remove the trim pin and the position aside the RH side heat shield.

-

Remove the nuts and position aside the wire harness.

Torque:

53 lb.in (6 Nm)

-

Remove the RH head lamp.

Refer to: Headlamp Assembly (417-01 Exterior Lighting, Removal and Installation).

-

Remove the PCM.

Refer to: Powertrain Control Module (PCM) (303-14A Electronic Engine Controls - 3.0L EcoBoost/3.0L EcoBoost – Hybrid (BQ), Removal and Installation).

-

Detach the wiring harness retainers and position aside the harness.

-

Detach the wiring harness retainers and position aside the harness.

-

Remove the bolts and the PCM bracket.

Torque:

53 lb.in (6 Nm)

-

-

Disconnect the IAT sensor electrical connector.

-

Detach the clip.

-

Detach electrical wire clips.

-

Loosen the clamps and position the air cleaner outlet pipes LH and RH aside.

Torque:

44 lb.in (5 Nm)

-

-

Remove the nut.

Torque:

80 lb.in (9 Nm)

-

Detach and remove the air cleaner from the isolators.

-

Loosen the clamp and remove the upper air cleaner outlet pipe.

Torque:

44 lb.in (5 Nm)

-

Loosen the RH

CAC intake pipe clamp.

Torque:

44 lb.in (5 Nm)

-

Loosen the bolt and remove the RH

CAC intake pipe.

Torque:

106 lb.in (12 Nm)

-

Loosen the clamp and remove RH

CAC intake pipe.

Torque:

44 lb.in (5 Nm)

-

Remove the hose clip and position aside the hose.

-

-

Loosen the hose clamp.

Torque:

44 lb.in (5 Nm)

-

Loosen the clamp and remove the CAC Y-pipe.

Torque:

44 lb.in (5 Nm)

-

Release the wire guides and position aside the wire harness.

-

Remove the fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Remove the fasteners and the fender flange finisher.

-

Disconnect the electrical connector and release the wire guides.

-

Release the wire guides.

-

Disconnect the electrical connectors and release the wire guides.

-

Release the wire guides and position aside the wire harness.

-

Disconnect the electrical connectors from the DCDC and remove the High Voltage Battery Cables from the vehicle.

compressor high voltage cable

-

Disconnect the electrical connector.

-

Release the wire guides, disconnect the electrical connector and remove the harness.

High Voltage 3 Phase AC -ISC (Inverter System Controller) to E-Motor Cable

-

Remove the retainers, disconnect the electrical connectors from the ISC and position aside the harness.

Torque:

97 lb.in (11 Nm)

-

-

Remove the harness retainer.

Torque:

53 lb.in (6 Nm)

-

Detach the wire guides.

-

Remove the retainers.

Torque:

53 lb.in (6 Nm)

-

NOTICE:

Only lower the transmission far enough to

access the electrical connector or damage to the wiring harness can

occur.

Remove the transmission.

Refer to: Transmission - 3.0L EcoBoost – Hybrid (BQ) (307-01B Automatic Transmission - 10-Speed Automatic Transmission – 10R80 MHT, Removal and Installation).

-

Remove the retainers and the hybrid drive unit electrical connector.

Torque:

97 lb.in (11 Nm)

Installation

-

To install, reverse the removal procedure.

-

NOTICE:

If the transmission is not positioned on the dowel pins, damage to the transmission may occur.

-

If the dowel pins were pulled out of the engine

block during removal, install new dowel pins in the engine block.

-

Clean and inspect the high voltage electrical connector gasket.

Removal

WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system...

Other information:

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Removal

Drain the cooling system.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding (303-03A Engine Cooling - 3.0L EcoBoost, General Procedures)...

Special Tool(s) /

General Equipment

Hose Clamp Remover/Installer

Removal

Remove the air cleaner.

Refer to: Air Cleaner (303-12 Intake Air Distribution and Filtering - 3.0L EcoBoost/3.0L EcoBoost – Hybrid (BQ), Removal and Installation)...

.jpg) WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system. The high-voltage system utilizes approximately

450 volts DC, provided through high-voltage cables to its components and

modules. The high-voltage cables and wiring are identified by orange

harness tape or orange wire covering. All high-voltage components are

marked with high-voltage warning labels with a high-voltage symbol.

Failure to follow these instructions may result in serious personal

injury or death.

WARNING:

To prevent the risk of high-voltage shock, always follow

precisely all warnings and service instructions, including instructions

to depower the system. The high-voltage system utilizes approximately

450 volts DC, provided through high-voltage cables to its components and

modules. The high-voltage cables and wiring are identified by orange

harness tape or orange wire covering. All high-voltage components are

marked with high-voltage warning labels with a high-voltage symbol.

Failure to follow these instructions may result in serious personal

injury or death.

.jpg) WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal and Installation - High Voltage Low Current Fuse - Plug-In Hybrid Electric Vehicle (PHEV)

Removal and Installation - High Voltage Low Current Fuse - Plug-In Hybrid Electric Vehicle (PHEV)