Lincoln Aviator 2020-2026 Service Manual / Powertrain / Automatic Transmission / Transmission Cooling - 10-Speed Automatic Transmission – 10R60 / Removal and Installation - Transmission Fluid Cooler

Lincoln Aviator: Transmission Cooling - 10-Speed Automatic Transmission – 10R60 / Removal and Installation - Transmission Fluid Cooler

Special Tool(s) / General Equipment

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Motorcraft® MERCON® ULV Automatic Transmission Fluid XT-12-QULV |

WSS-M2C949-A, MERCON® ULV |

Removal

-

With the vehicle in N, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

NOTE: Be prepared to collect escaping fluid.

Loosen the clamps and disconnect the coolant hoses from the transmission fluid cooler.

Use the General Equipment: Locking Pliers

.jpg) |

-

NOTE: If equipped.

Remove the bolt.

.jpg) |

-

NOTE: Be prepared to collect escaping fluid.

Remove the bolt, the nuts and the transmission fluid cooler.

.jpg) |

Installation

-

Inspect the O-ring seals and install new O-ring seals if

necessary. Lubricate the O-ring seals before installing the

transmission fluid cooler.

Material: Motorcraft® MERCON® ULV Automatic Transmission Fluid / XT-12-QULV (WSS-M2C949-A, ) (MERCON® ULV)

.jpg) |

-

NOTICE: Make sure the oil cooler is completely installed against the transmission before tightening, or damage to the cooler could result.

Install the transmission fluid cooler and loosely install the bolt and the nuts by hand.

.jpg) |

-

NOTICE: Make sure the oil cooler is completely installed against the transmission before tightening, or damage to the cooler could result.

Tighten the bolt and nuts in the sequence shown.

Torque: 18 lb.ft (25 Nm)

.jpg) |

-

NOTE: If equipped.

Install the bolt.

Torque: 18 lb.ft (25 Nm)

.jpg) |

-

Connect the coolant hoses to the transmission fluid cooler.

.jpg) |

-

Check the engine coolant level and adjust as necessary.

Refer to: Engine Cooling System Draining, Vacuum Filling and Bleeding (303-03A Engine Cooling - 3.0L EcoBoost, General Procedures).

-

Check the transmission fluid level and adjust as necessary.

Refer to: Transmission Fluid Level Check (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, General Procedures).

General Procedures - Transmission Fluid Cooler - Backflushing and Cleaning

General Procedures - Transmission Fluid Cooler - Backflushing and Cleaning

Special Tool(s) /

General Equipment

Transmission Cooling System Heated Flusher

Materials

Name

Specification

Motorcraft® MERCON® ULV Automatic Transmission FluidXT-12-QULV

WSS-M2C949-A, MERCON® ULV

Flushing

NOTE:

Use transmission fluid specified for this

transmission...

Other information:

Lincoln Aviator 2020-2026 Service Manual: General Procedures - High Voltage Battery Leak Test - Plug-In Hybrid Electric Vehicle (PHEV)

Leak detection NOTE: This test is meant to be a secondary check after a service procedure is performed on the high voltage battery when a seal is disturbed. It is important to follow the workshop manual service procedure to verify a high voltage battery is sealed correctly...

Lincoln Aviator 2020-2026 Service Manual: Description and Operation - Supplemental Climate Control - Overview

Overview The cabin coolant heater system provides warm coolant to the heater core to warm the passenger compartment whenever the front DATC module requests heat and the HEV is in a driving mode, remote started, or doing Cabin Drive Conditioning. The climate control system uses the cabin coolant heater to heat the passenger compartment in place of the heater core in low ambient temperatures...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Garage Door Opener

- Remove and Reinstall the Battery

- Interior Lamps

- New on site

- Most important about car

Fastening the Seatbelts

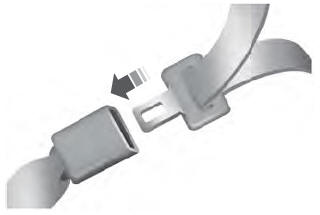

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2026 www.liaviator2.com