Lincoln Aviator: Fuel Charging and Controls - 3.0L EcoBoost/3.0L EcoBoost – Hybrid (BQ) / Removal and Installation - High-Pressure Fuel Pump

Removal

NOTICE:

Do not loosen any fittings or plugs on the high-pressure fuel pump.

-

With the vehicle in NEUTRAL, position it on a hoist.

Refer to: Jacking and Lifting (100-02 Jacking and Lifting, Description and Operation).

-

Release the fuel system pressure.

Refer to: Fuel System Pressure Release (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

Disconnect the battery negative cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

Remove the cowl panel.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

Remove the intake manifold.

Refer to: Intake Manifold (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

-

With hybrid engine only, remove the wire harness retaining nut and move the harness out of the way.

-

Detach the coolant hose retainer.

-

NOTE:

When removing or installing the fuel injection pump

noise insulator, spreading the openings will reduce the risk of damage.

Remove the fuel injection pump noise insulator.

-

NOTICE:

To release the fuel pressure in the high-pressure

fuel tube, wrap the high-pressure fuel tube flare nuts with a shop towel

to absorb any residual fuel pressure during the loosening of the

high-pressure fuel tube flare nuts.

Remove the high-pressure fuel tube bracket nuts.

Disconnect the high-pressure fuel tube flare nuts, then remove and

discard the high-pressure fuel tube.

-

Remove the high-pressure fuel pump shield nuts.

-

Remove the high-pressure fuel pump shield bolt, then position the shield up and out of the way.

-

Disconnect the high-pressure fuel pump fuel feed spring

lock coupling, then remove the high-pressure fuel pump shield.

Refer to: Spring Lock Couplings (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

Disconnect the high-pressure fuel pump fuel electrical connector.

-

Alternately loosen the high-pressure fuel pump nuts one

complete revolution at a time and remove, then remove the high-pressure

fuel pump.

-

Remove and discard the high-pressure fuel pump O-ring seal.

-

Remove the high-pressure fuel pump roller tappet.

-

Inspect the high-pressure fuel pump roller tappet. If

any flat spots or scoring are found, especially in the indicated areas,

then inspect the high-pressure fuel pump and the high-pressure fuel pump

roller tappet drive lobe. Install new components as needed.

-

If needed, remove the high-pressure fuel pump mounting studs.

Installation

-

NOTICE:

Only rotate the crankshaft Clockwise (CW) or damage to the engine may occur.

NOTICE:

The drive lobe for the high-pressure fuel pump must

be at BDC (bottom dead center) for the high-pressure fuel pump

installation.

Using the crankshaft pulley bolt, turn the crankshaft

until the high-pressure fuel pump drive lobe is at BDC (bottom dead

center).

-

Apply clean engine oil to the high-pressure fuel pump

mounting pedestal bore, the drive lobe and the roller tappet.

Refer to: Specifications (303-01A Engine - 3.0L EcoBoost, Specifications).

-

Install the high-pressure fuel pump roller tappet.

-

NOTE:

Apply clean engine oil to the high-pressure fuel pump O-ring seals.

Install a new high-pressure fuel pump O-ring seal and lubricate with clean engine oil.

Refer to: Specifications (303-01A Engine - 3.0L EcoBoost, Specifications).

-

If removed, install and tighten the high-pressure fuel pump mounting studs.

Torque:

106 lb.in (12 Nm)

-

Install the high-pressure fuel pump, then install the

mounting nuts finger tight. Alternately tighten each high-pressure fuel

pump nut one complete revolution until seated. Tighten the fuel

high-pressure fuel pump nuts in the following 2 stages.

Torque:

Stage 1:

177 lb.in (20 Nm)

Stage 2:

45°

-

Connect the high-pressure fuel pump electrical connector.

-

Position the high-pressure fuel pump shield so that the high-pressure fuel pump fuel feed can be connected.

-

Connect the high-pressure fuel pump fuel feed spring lock coupling.

Refer to: Spring Lock Couplings (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

Install the high-pressure fuel pump shield, then install and tighten the bolt.

Torque:

18 lb.ft (25 Nm)

-

Install and tighten the high-pressure fuel pump shield nuts,

Torque:

18 lb.ft (25 Nm)

-

NOTICE:

In stage 4, if the torque required to tighten any

flare nut on the new high-pressure fuel tube reaches or exceeds 37 lb.ft

(50 Nm), then that high pressure fuel tube must be discarded and

replaced with another new high-pressure fuel tube.

NOTE:

Calculate the correct torque wrench setting for the

following torque using the Torque Wrench Adapter Formulas.

NOTE:

Make sure that a new high-pressure fuel tube is installed.

Install the high-pressure fuel tube and bracket nuts,

tighten the high-pressure fuel tube flare nuts and bracket nuts finger

tight.

Torque:

Stage 1:

Tighten the high-pressure fuel tube bracket nuts to, :

89 lb.in (10 Nm)

Stage 2:

Tighten the high-pressure fuel tube flare nuts to, :

62 lb.in (7 Nm)

Stage 3:

Tighten the high-pressure fuel tube flare nuts to, :

89 lb.in (10 Nm)

Stage 4:

Tighten the high-pressure fuel tube flare nuts an additional, :

25°

.jpg) |

|

-

NOTE:

When removing or installing the fuel injection pump

noise insulator, spreading the openings will reduce the risk of damage.

Install the fuel injection pump noise insulator.

-

Install the intake manifold.

Refer to: Intake Manifold (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

-

Attach the coolant hose retainer.

-

With hybrid engine only, install the harness, then install and tighten the wire harness retaining nut.

Torque:

106 lb.in (12 Nm)

-

Install the cowl panel.

Refer to: Cowl Panel (501-02 Front End Body Panels, Removal and Installation).

-

Connect the battery negative cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

-

Pressurize the fuel system.

Refer to: Fuel System Pressure Release (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

Removal

All Vehicles

NOTE:

The fuel pump driver module is located on the

bottom side of the left front floor panel, above the sound insulation

panel...

Removal and Installation

The high-pressure fuel pump drive unit is part of the

right cylinder head and is removed in the right camshaft procedure...

Other information:

System Diagram

Item

Description

1

SOBDMC

2

BCMC

3

PCM

4

Cabin Coolant Heater

5

Cabin heater coolant temperature sensor

6

Cabin heater coolant pump

7

Ambient Air Temperature (AAT) sensor

8

Engine Coolant Temperature (ECT) sensor

Network Message Chart - Module Network Input Messages - SOBDMC Cabin Coolant Heater

Broadcast Message

Originating Module

Message Purpose

Engine Coolant Temperature Data

PCM

This message contains raw value from the engine coolant temperature sensor...

Removal

WARNING:

Vent all air pressure from the air suspension system prior

to disconnecting or removing any air suspension components. It is

dangerous to remove air suspension components while under pressure.

Failure to follow this instruction may result in serious personal

injury...

Categories

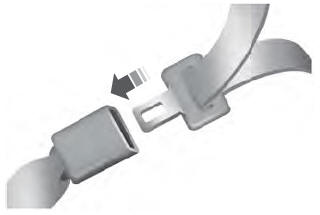

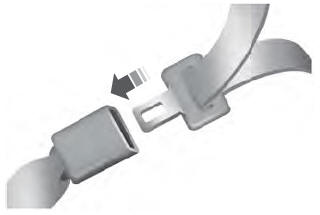

The front outboard and rear safety restraints

in the vehicle are combination lap and

shoulder belts.

Insert the belt tongue into the proper

buckle (the buckle closest to the direction

the tongue is coming from) until you hear

a snap and feel it latch. Make sure that

you securely fasten the tongue in the

buckle.

To unfasten, press the release button

and remove the tongue from the buckle.

read more

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal and Installation - Fuel Pump Driver Module (FPDM)

Removal and Installation - Fuel Pump Driver Module (FPDM) Removal and Installation - High-Pressure Fuel Pump Drive Unit

Removal and Installation - High-Pressure Fuel Pump Drive Unit