Lincoln Aviator: Exhaust System - 3.0L EcoBoost / Diagnosis and Testing - Exhaust System

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Diagnostic Trouble Code Chart

| Module | DTC | Description | Action |

|---|---|---|---|

| PCM | P0544:00 | Exhaust Gas Temperature Sensor Circuit (Bank 1 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

| PCM | P0545:00 | Exhaust Gas Temperature Sensor Circuit Low (Bank 1 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

| PCM | P0546:00 | Exhaust Gas Temperature Sensor Circuit High (Bank 1 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

| PCM | P0547:00 | Exhaust Gas Temperature Sensor Circuit (Bank 2 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

| PCM | P0548:00 | Exhaust Gas Temperature Sensor Circuit Low (Bank 2 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

| PCM | P0549:00 | Exhaust Gas Temperature Sensor Circuit High (Bank 2 Sensor 1): No Sub Type Information | GO to Pinpoint Test RB |

Global Customer Symptom Code (GCSC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Global Customer Symptom Code Chart

| Customer Symptom | Action |

|---|---|

| Fit/Finish/Body > Paint/Finish > Exhaust > Corrosion/Rust | GO to Pinpoint Test C |

| Start/Run/Move > Noise > Exhaust > Always | GO to Pinpoint Test D |

| Driving Performance > Lack/Loss of Power > Acceleration > Always | GO to Pinpoint Test A |

| Safe & Secure > Smoke/Odor > Exhaust > Hot | GO to Pinpoint Test B |

| Runs Rough > Hesitates/Stumble > Acceleration | GO to Pinpoint Test RB |

Symptom Chart(s)

Symptom Chart - Exhaust System

NOTE: Aftertreatment components consist of some or all of the following components: Catalytic Converters, Gasoline Particulate Filters, Diesel Particulate Filters, Selective Catalytic Reduction Catalysts, Exhaust Gas Heat Exchanger.

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to: Diagnostic Methods (100-00 General Information, Description and Operation).

Symptom Chart

| Condition | Actions |

|---|---|

| Lack of power - vehicle performance complaint |

|

| Odour from vehicle - possible sign of smoke |

|

| Surface rust or degradation of surface treatment |

|

| Noise such as buzzing, drumming, thumping, ringing or hissing coming from exhaust system |

|

Pinpoint Tests

.jpg) PINPOINT TEST A : LACK OF POWER

PINPOINT TEST A : LACK OF POWER|

NOTE: Aftertreatment components consist of some or all of the following: Catalytic Converters, Gasoline Particulate Filters, Diesel Particulate Filters, Selective Catalytic Reduction Catalysts. Normal Operation and Fault Conditions

REFER to: Exhaust System - Overview (309-00A Exhaust System - 3.0L EcoBoost, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| A1 CHECK THE EXHAUST SYSTEM FOR SIGNS OF DAMAGE | ||||

Is damage to the aftertreatment components and associated sensors found?

|

||||

| A2 CHECK THE EXHAUST SYSTEM FOR OBSTRUCTIONS OR RESTRICTED FLOW | ||||

Is any flow restricting damage to the exhaust components seen?

|

.jpg) PINPOINT TEST B : ODOUR FROM VEHICLE

PINPOINT TEST B : ODOUR FROM VEHICLE|

NOTE: Aftertreatment components consist of some or all of the following: Catalytic Converters, Gasoline Particulate Filters, Diesel Particulate Filters, Selective Catalytic Reduction Catalysts. Normal Operation and Fault Conditions

REFER to: Exhaust System - Overview (309-00A Exhaust System - 3.0L EcoBoost, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| B1 CHECK FOR DAMAGED AFTERTREATMENT COMPONENTS ASSOCIATED SENSORS | ||||

Have the aftertreatment components or associated electronic sensors incurred damage?

|

||||

| B2 CHECK FOR INCORRECT FUEL OR FUEL WITH A HIGH SULFUR CONTENT | ||||

Does the fuel tank contain incorrect fuel or fuel high in sulfur content?

|

||||

| B3 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||

Are the powertrain controls operating correctly?

|

.jpg) PINPOINT TEST C : SURFACE RUST OR DEGRADATION OF SURFACE TREATMENT

PINPOINT TEST C : SURFACE RUST OR DEGRADATION OF SURFACE TREATMENT|

NOTE: Surface rust is a characteristic of materials used on exhaust systems. Exposure to heat or road salt may result in surface rust. Normal Operation and Fault Conditions

REFER to: Exhaust System - Overview (309-00A Exhaust System - 3.0L EcoBoost, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| C1 CHECK THE EXHAUST SYSTEM FOR PERFORATIONS, RUST OR DAMAGE | ||||

Are perforations, rust or damage present?

|

||||

| C2 CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE) OPERATION | ||||

Are the powertrain controls operating correctly?

|

.jpg) PINPOINT TEST D : NOISE FROM EXHAUST SYSTEM

PINPOINT TEST D : NOISE FROM EXHAUST SYSTEM|

NOTE: Aftertreatment components consist of some or all of the following: Catalytic Converters, Gasoline Particulate Filters, Diesel Particulate Filters, Selective Catalytic Reduction Catalysts. Normal Operation and Fault Conditions

REFER to: Exhaust System - Overview (309-00A Exhaust System - 3.0L EcoBoost, Description and Operation). Possible Sources

Visual Inspection and Pre-checks

|

||||

| D1 CHECK THE EXHAUST SYSTEM FASTENERS | ||||

Was exhaust noise still present after confirming all exhaust system fasteners are tightened to specification?

|

||||

| D2 INSPECT THE EXHAUST ISOLATORS AND HANGER BRACKETS | ||||

Were exhaust system isolators and hanger brackets found to be in correct alginment and in good condition?

|

||||

| D3 CHECK FOR MISSING OR DAMAGED EXHAUST HEAT SHIELDS | ||||

Were the exhaust heat shields found to be present and in correct alignment?

|

||||

| D4 CHECK THE EXHAUST SYSTEM FOR ALIGNMENT | ||||

Was the exhaust noise seen to originate from contact between the exhaust system and the surrounding components/vehicle body?

|

||||

| D5 CHECK THE EXHAUST SYSTEM FOR INTERNAL DAMAGE | ||||

Was noise such as rattling, clanging or twanging heard within the exhaust components?

|

||||

| D6 CHECK THE EXHAUST SYSTEM FOR LEAKS | ||||

Were leaks found?

|

||||

| D7 CHECK FOR COOL DOWN PINGING | ||||

Was the exhaust complaint found to be cool down pinging?

|

.jpg) PINPOINT TEST RB : EXHAUST GAS TEMPERATURE (EGT) SENSOR

PINPOINT TEST RB : EXHAUST GAS TEMPERATURE (EGT) SENSOR.jpg) WARNING:

Manual regeneration of the particulate filter causes

the exhaust gas to quickly get very hot. Initiate a manual regeneration

only when the vehicle is on the ground with the area around the

tailpipe free of people, obstructions, foreign material or other items.

Failure to follow these instructions may result in serious personal

injury.

WARNING:

Manual regeneration of the particulate filter causes

the exhaust gas to quickly get very hot. Initiate a manual regeneration

only when the vehicle is on the ground with the area around the

tailpipe free of people, obstructions, foreign material or other items.

Failure to follow these instructions may result in serious personal

injury.

NOTE: Regeneration may occur during normal operation. During regeneration, diagnostic procedures may display biased values. If a regeneration occurs during diagnostic procedures, allow the process to complete before continuing diagnostics.

Normal Operation and Fault Conditions

Refer to the DTC Fault Trigger Conditions.

DTC Fault Trigger Conditions

| DTC | Description | Fault Trigger Condition |

|---|---|---|

| PCM P0544:00 | Exhaust Gas Temperature Sensor Circuit - Bank 1 Sensor 1: No Sub Type Information | Sets when the PCM detects, after 5 minutes of driving following a 6 hour soak, the exhaust gas temperature bank 1, sensor 1 sensor temperature does not correlate to the modeled temperature of 170ºC (338ºF). The PCM monitors the operation of the exhaust gas temperature bank 1, sensor 1 to determine if the sensor responds to the increase in temperature of the exhaust gas during vehicle operation. The PCM then compares the measured temperature to a modeled value. |

| PCM P0545:00 | Exhaust Gas Temperature Sensor Circuit Low - Bank 1 Sensor 1: No Sub Type Information | Sets when the PCM detects the exhaust gas temperature bank 1, sensor 1 voltage is less than 0.10 volt for greater than 15 seconds. |

| PCM P0546:00 | Exhaust Gas Temperature Sensor Circuit High - Bank 1 Sensor 1: No Sub Type Information | Sets when the PCM detects the exhaust gas temperature bank 1, sensor 1 voltage is greater than 4.90 volts for greater than 15 seconds. |

| PCM P0547:00 | Exhaust Gas Temperature Sensor Circuit - Bank 2 Sensor 1: No Sub Type Information | Sets when the PCM detects, after 5 minutes of driving following a 6 hour soak, the exhaust gas temperature bank 2, sensor 1 temperature does not correlate to the modeled temperature of 170ºC (338ºF). The PCM monitors the operation of the exhaust gas temperature bank 2, sensor 1 to determine if the sensor responds to the increase in temperature of the exhaust gas during vehicle operation. The PCM then compares the measured temperature to a modeled value. |

| PCM P0548:00 | Exhaust Gas Temperature Sensor Circuit Low - Bank 2 Sensor 1: No Sub Type Information | Sets when the PCM detects the exhaust gas temperature bank 2, sensor 1 voltage is less than 0.10 volt for greater than 15 seconds. |

| PCM P0549:00 | Exhaust Gas Temperature Sensor Circuit High - Bank 2 Sensor 1: No Sub Type Information | Sets when the PCM detects the exhaust gas temperature bank 2, sensor 1 voltage is greater than 4.90 volts for greater than 15 seconds. |

Possible Sources

- Exhaust leak

- Exhaust gas temperature sensor circuitry concern

- Exhaust gas temperature sensor (5J213)

- PCM (12A650)

.png) Internet Explorer version 11 or greater is required to perform this Pinpoint Test.

Internet Explorer version 11 or greater is required to perform this Pinpoint Test. Diagnosis and Testing - Catalyst System

Diagnosis and Testing - Catalyst System

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Diagnosis and Testing - Particulate Filter System

Diagnosis and Testing - Particulate Filter System

Diagnostic Trouble Code (DTC) Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.REFER to: Diagnostic Methods (100-00 General Information, Description and Operation)...

Other information:

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Ignition Switch - Vehicles With: Keyless Vehicle System

Removal NOTE: Removal steps in this procedure may contain installation details. Remove and disconnect the switch pack. Remove trim panel. Remove trim panel. Remove the retainer...

Lincoln Aviator 2020-2026 Owners Manual: Charge Time Settings

Follow these steps to set a preferred charge time for a charging location. Select Charge Preferences on the Charge Settings screen. Select Charge Time Setup on the Edit Charge Preferences screen. Select Add New Location on the Charge Times screen...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Locking and Unlocking

- Resetting the System

- Tire Change Procedure

- New on site

- Most important about car

Fastening the Seatbelts

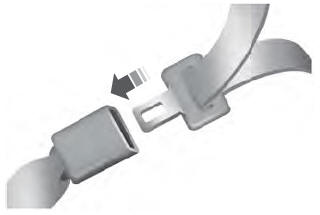

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

.jpg) PINPOINT TEST A : LACK OF POWER

PINPOINT TEST A : LACK OF POWER