Lincoln Aviator: Engine - 3.0L EcoBoost / Removal - Engine Block Skirt Stiffener

Special Tool(s) /

General Equipment

.jpg) |

205-153

(T80T-4000-W)

Handle |

|

303-1246

Engine Spreader Bar

TKIT-2006UF-FLM

TKIT-2006UF-ROW |

|

303-1247

VCT Spark Plug Tube Seal Remover and Installer

TKIT-2006UF-FLM

TKIT-2006UF-ROW |

.jpg) |

303-1634

Lift Eyes (2)

TKIT-2014D-ROW3

TKIT-2014D-FL_ROW |

.jpg) |

303-409

(T92C-6700-CH)

Remover, Crankshaft Seal

TKIT-1992-FH/FMH/FLMH

TKIT-1993-LMH/MH |

| Floor Crane |

| Mounting Stand |

| Plastic Scraper |

| Flat-Bladed Screwdriver |

Materials

| Name |

Specification |

Motorcraft® Silicone Gasket Remover

ZC-30-A |

-

|

Motorcraft® Metal Surface Prep Wipes

ZC-31-B |

-

|

Motorcraft® Metal Brake Parts Cleaner

PM-4-A, PM-4-B |

-

|

NOTICE:

During engine repair procedures, cleanliness is extremely

important. Any foreign material, including any material created while

cleaning gasket surfaces, that enters the oil passages, coolant passages

or the oil pan, can cause engine failure.

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles. When removing any turbocharger or engine air intake

system component, ensure that no debris enters the system. Failure to do

so may result in damage to the turbocharger.

LHD AWD/LHD RWD

-

Remove the engine from the vehicle.

Refer to: Engine (303-01A Engine - 3.0L EcoBoost, Removal).

-

Remove the bolts and the flexplate.

-

Remove the crankshaft sensor ring.

-

Inspect the crankshaft sensor ring for damage. If the

crankshaft sensor ring has been dropped or has any visual damage, it

must be discarded.

-

Remove the nut and the heat shield.

-

-

Disconnect the CKP sensor electrical connector.

-

Remove the stud bolt and the CKP sensor.

-

Remove the bolts and the crankshaft rear seal and retainer plate.

-

Discard the crankshaft rear seal and retainer plate.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges which make leak paths. Use a

plastic scraping tool to remove all traces of old sealant.

Clean and inspect the mating surface.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

-

Using a floor crane, install the engine on a mounting stand.

Remove Special Service Tool: 303-1246

Engine Spreader Bar.

, 303-1634

Lift Eyes (2).

Use the General Equipment: Floor Crane

Use the General Equipment: Mounting Stand

-

-

Remove the bolts and the LH engine mount.

-

NOTE:

AWD shown, RWD similar.

-

Remove and discard the nuts and bolts.

-

Remove the RH engine mount.

-

NOTE:

AWD shown, RWD similar.

Remove and discard the studs.

LHD RWD

-

Remove the bolt and the engine mount spacer.

LHD AWD

-

Remove the bolts and the front axle disconnect actuator.

-

Remove and discard the seal.

-

Remove and discard the studs.

-

Remove the bolts and the front axle assembly.

-

Remove and discard the front axle assembly seal.

LHD AWD/LHD RWD

-

Remove the oil level indicator.

-

-

Detach the fuel tube retainer.

-

Disconnect the quick release coupling and remove the fuel tube assembly.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

Disconnect the quick release coupling and remove the EVAP tube.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

Remove the bolts and the A/C compressor.

-

Remove the bolts and the air cleaner outlet pipe.

-

Inspect the O-ring seal and replace as necessary.

-

-

Detach the wiring harness retainer.

-

Loosen the clamp and remove the CAC inlet pipe.

-

Disconnect the quick release couplings and remove the crankcase vent tube.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

-

Remove the stud bolt and the ground wire.

-

Slide the wiring harness insulator up.

-

Disconnect the CHT electrical connector.

-

-

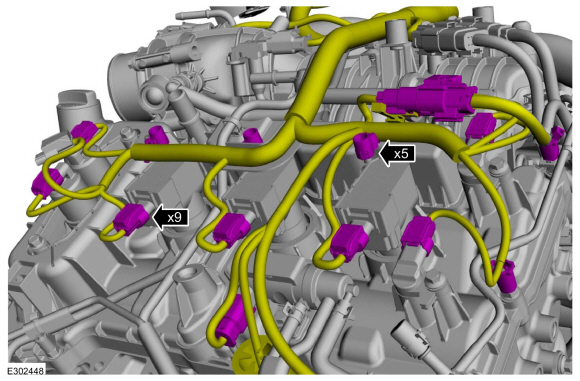

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Remove the stud bolt and the ground wire from the rear of the RH cylinder head.

-

Detach the wiring harness retainer.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

-

Disconnect the wiring harness electrical connectors.

-

Detach the wiring harness retainers.

-

Remove the wiring harness from the engine.

-

-

Release the clamp and disconnect the vacuum hose.

-

Detach the vacuum harness retainer.

-

Disconnect the vacuum harness quick release coupling.

Refer to: Quick Release Coupling (310-00A Fuel System - General Information - 3.0L EcoBoost, General Procedures).

-

-

Detach the vacuum harness retainers.

-

Remove the vacuum harness from the engine.

-

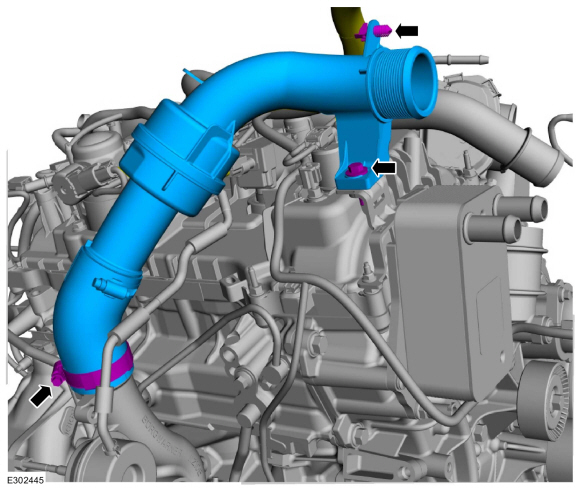

Remove the bolts and the coolant pipe.

-

Inspect the O-ring seal and replace as necessary.

-

Loosen the bolts and remove the intake manifold.

-

-

Remove and inspect the gaskets, replace as necessary.

-

NOTICE:

To release the fuel pressure in the high-pressure

fuel tube, wrap the high-pressure fuel tube flare nuts with a shop towel

to absorb any residual fuel pressure during the loosening of

high-pressure fuel tube flare nuts.

-

Loosen the fuel tube flare nut fittings.

-

Remove and discard the fuel tube.

-

NOTE:

Alternately loosen the high-pressure fuel pump nuts one revolution at a time.

Remove the nuts and the high-pressure fuel pump.

-

Remove and discard the high-pressure fuel pump O-ring seal.

-

Remove the high-pressure fuel pump tappet.

-

Inspect the high-pressure fuel pump roller tappet. If

any flat spots or scoring are found, especially in the indicated areas,

then inspect the high-pressure fuel pump and the high-pressure fuel pump

roller tappet drive lobe. Install new components as necessary.

-

If damaged, remove and discard the studs.

-

Remove the fasteners and the TC oil return tube.

-

Remove and discard the TC oil return tube tube-to-engine block gasket.

-

Remove and discard the TC oil return tube O-ring seal.

-

NOTICE:

Inspect for blockage in the turbocharger tube. Check

the tube, the sealing surfaces and the flange for flatness and damage.

Ensure that the retaining bracket is not bent, check for square-ness of

the retaining bracket to the O-ring area. Use brake cleaner and a NYLON

brush to clean. DO NOT USE A METAL BRUSH; DAMAGE TO SEALING AREA WILL

RESULT IN LEAKS.

Clean and inspect the TC oil return tube.

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

-

Remove the bolts and the oil cooler.

-

Inspect the oil cooler. If metal or aluminum material is

present in the oil cooler, mechanical concerns exist. Failure to

correct these concerns may cause engine failure.

Refer to: Engine (303-00 Engine System - General Information, Diagnosis and Testing).

-

Remove and discard the oil cooler gasket.

-

-

Remove the bolts and the coolant pump pulley.

-

Remove the bolt and the idler pulley.

-

Remove the bolt and the idler pulley.

-

Remove the bolts and the coolant pump.

-

Remove and discard the coolant pump gasket and seal.

-

NOTE:

When removing the ignition coil-on-plugs, a slight twisting motion will break the seal and ease removal.

Remove the stud bolts and the LH ignition coil-on-plugs.

-

NOTE:

When removing the ignition coil-on-plugs, a slight twisting motion will break the seal and ease removal.

Remove the stud bolts and the RH ignition coil-on-plugs.

-

Remove the nuts and the bracket.

-

Loosen the fasteners and remove the valve cover.

-

-

Remove and discard the gaskets.

-

Clean the valve cover gasket groove with soap and water or a suitable solvent.

-

Inspect the spark plug seals. Remove any damaged seals using the special tools.

Use Special Service Tool: 205-153

(T80T-4000-W)

Handle.

, 303-1247

VCT Spark Plug Tube Seal Remover and Installer.

-

Loosen the fasteners and remove the valve cover.

-

-

Remove and discard the gaskets.

-

Clean the valve cover gasket groove with soap and water or a suitable solvent.

-

Inspect the spark plug seals. Remove any damaged seals using the special tools.

Use Special Service Tool: 205-153

(T80T-4000-W)

Handle.

, 303-1247

VCT Spark Plug Tube Seal Remover and Installer.

-

Remove the crankshaft pulley bolt.

-

NOTE:

Use a universal puller (such as an OTC 6667, or equivalent).

Using a universal puller, remove the crankshaft pulley.

-

NOTICE:

Use care not to damage the engine front cover or the crankshaft when removing the seal.

-

Install the crankshaft pulley bolt.

-

Using the special tool, remove and discard the crankshaft front oil seal.

Use Special Service Tool: 303-409

(T92C-6700-CH)

Remover, Crankshaft Seal.

-

NOTE:

Retain the original crankshaft pulley bolt for turning the crankshaft while the pulley is removed.

Remove the crankshaft pulley bolt.

-

Remove the bolts and the oil pan.

-

Remove and discard the oil pan gasket.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges, which make leak paths. Use a

plastic scraping tool to remove traces of sealant.

Make sure that the mating faces of the engine block and

engine front cover are clean and free of foreign material.

-

NOTE:

There are 5 different types of fasteners, note location of each fastener for assembly.

Remove the engine front cover fasteners.

-

Using a large flat-bladed screwdriver and the indicated

pry pads, release the sealer and remove the engine front cover.

Use the General Equipment: Flat-Bladed Screwdriver

-

Remove and discard the engine front cover gaskets.

-

Remove and discard the oil gallery seal (6G068).

-

NOTICE:

Only use a 3M™ Roloc® Bristle Disk (2-in white, part

number 07528) to clean the engine front cover. Do not use metal

scrapers, wire brushes or any other power abrasive disk to clean front

cover.

-

Clean the engine front cover using a 3M™ Roloc®

Bristle Disk (2-in white, part number 07528) in a suitable tool turning

at the recommended speed of 15,000 rpm.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

-

Thoroughly wash the engine front cover to remove any

foreign material, including any abrasive particles created during the

cleaning process.

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

.jpg) |

|

-

NOTICE:

Place clean, lint-free shop towels over exposed

engine cavities. Carefully remove the towels so foreign material is not

dropped into the engine. Any foreign material (including any material

created while cleaning gasket surfaces) that enters the oil passages may

cause engine failure.

NOTICE:

Do not use wire brushes, power abrasive discs or 3M™

Roloc® Bristle Disk (2-in white part number 07528) to clean the sealing

surfaces. These tools cause scratches and gouges that make leak paths.

They also cause contamination that will cause premature engine failure.

Remove all traces of the gasket.

Make sure that the mating faces of the engine block are clean and free of foreign material.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

.jpg) |

|

-

NOTICE:

Rotate the crankshaft utilizing only the original

crankshaft pulley bolt. Failure to follow this direction may cause

damage to the crankshaft and result in engine failure.

Install the original crankshaft pulley bolt.

-

NOTICE:

The VCT units have 2 timing marks on them, a triangle and a circle. For removal and installation of the RH side the triangle marks are used.

-

Rotate the crankshaft clockwise.

-

Position the crankshaft sprocket keyway at the 11 o'clock position.

-

Verify the triangle timing marks on the VCT units are at the 2 o'clock (intake) and 11 o'clock (exhaust) positions. If the circle timing marks are at these positions the crankshaft must be turned clockwise one revolution (360 degrees).

-

Remove the bolts and the RH timing chain tensioner.

-

Remove the RH timing chain tensioner arm.

-

Remove the bolts and the RH timing chain guide.

-

Remove the RH timing chain.

-

Remove and discard the crankshaft pulley bolt.

-

Remove the timing chain sprocket.

-

Remove the bolts and the splash shield.

-

Slide the oil pump drive belt off of the crankshaft sprocket and remove the belt.

-

-

Remove the bolts and the oil return tube,

-

Remove the bolt and the oil control solenoid.

-

Remove and discard the O-ring seals.

-

Remove the bolts and the oil pump.

-

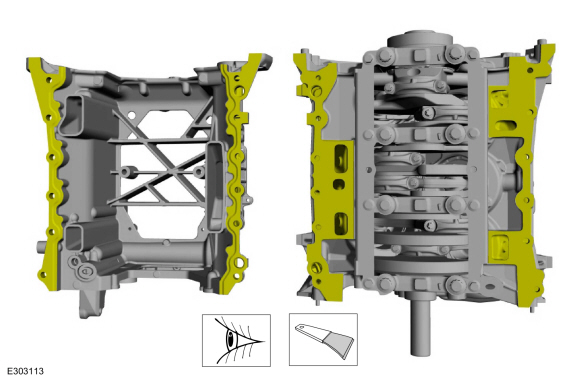

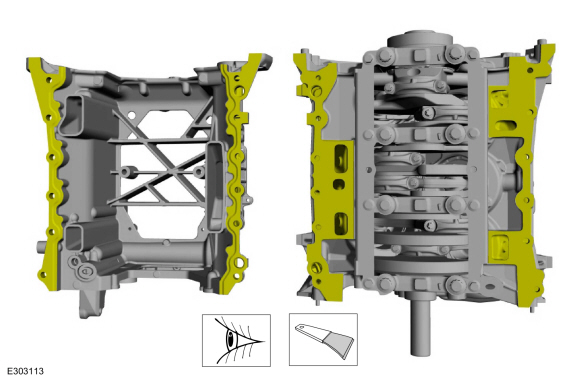

Remove the engine block skirt stiffener bolts.

-

Using a suitable pry bar at the pry pad locations,

release the engine block skirt stiffener-to-engine block seal.

-

-

Remove the engine block skirt stiffener.

-

Remove and discard the oil seal.

-

NOTICE:

Do not use metal scrapers, wire brushes, power

abrasive discs or other abrasive means to clean the sealing surfaces.

These tools cause scratches and gouges which make leak paths. Use a

plastic scraping tool to remove all traces of old sealant.

Clean and inspect the mating surfaces.

Refer to: RTV Sealing Surface Cleaning and Preparation (303-00 Engine System - General Information, General Procedures).

Use the General Equipment: Plastic Scraper

Material: Motorcraft® Silicone Gasket Remover

/ ZC-30-A

Material: Motorcraft® Metal Brake Parts Cleaner

/ PM-4-A, PM-4-B

Material: Motorcraft® Metal Surface Prep Wipes

/ ZC-31-B

|

|

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

204-592Separator, Lower Arm Ball JointTKIT-2006C-FFMFLMTKIT-2006C-LMTKIT-2006C-ROW

205-832Remover, HalfshaftTKIT-2006C-FFMFLMTKIT-2006C-LMTKIT-2006C-ROW

303-1246Engine Spreader BarTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1634Lift Eyes (2)TKIT-2014D-ROW3TKIT-2014D-FL_ROW

Tie Rod End Remover

Adjustable Mounting Arm

Cable Ties

Powertrain Jack

Wooden Block

Materials

Name

Specification

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B

-

NOTICE:

The turbocharger compressor vanes can be damaged by even the

smallest particles...

Special Tool(s) /

General Equipment

205-153

(T80T-4000-W)

Handle

303-1246Engine Spreader BarTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1247VCT Spark Plug Tube Seal Remover and InstallerTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1248Camshaft holding toolsTKIT-2006UF-FLMTKIT-2006UF-ROW

303-1634Lift Eyes (2)TKIT-2014D-ROW3TKIT-2014D-FL_ROW

303-1696Camshaft holding fixture

303-409

(T92C-6700-CH)

Remover, Crankshaft SealTKIT-1992-FH/FMH/FLMHTKIT-1993-LMH/MH

Floor Crane

Mounting Stand

Plastic Scraper

Flat-Bladed Screwdriver

Materials

Name

Specification

Motorcraft® Silicone Gasket RemoverZC-30-A

-

Motorcraft® Metal Surface Prep WipesZC-31-B

-

Motorcraft® Metal Brake Parts CleanerPM-4-A, PM-4-B

-

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Other information:

1 Do not exceed one year or 12,500 mi (20,000 km) between service intervals.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes.

1 Perform this maintenance item every 3 years. Do not exceed the designated

time for the interval...

Note: Do not rock the vehicle if the engine

is not at normal operating temperature or

damage to the transmission could occur.

Note: Do not rock the vehicle for more than

a minute or damage to the transmission and

tires could occur, or the engine could

overheat...

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Removal - Engine

Removal - Engine Disassembly - Engine

Disassembly - Engine