Lincoln Aviator 2020-2026 Service Manual / Chassis / Suspension / Vehicle Dynamic Suspension / Removal and Installation - Air Suspension Compressor

Lincoln Aviator: Vehicle Dynamic Suspension / Removal and Installation - Air Suspension Compressor

Removal

.jpg) WARNING:

Vent all air pressure from the air suspension system prior

to disconnecting or removing any air suspension components. It is

dangerous to remove air suspension components while under pressure.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Vent all air pressure from the air suspension system prior

to disconnecting or removing any air suspension components. It is

dangerous to remove air suspension components while under pressure.

Failure to follow this instruction may result in serious personal

injury.

NOTE: Removal steps in this procedure may contain installation details.

-

If installing a new air suspension compressor, connect

the scan tool and upload the module configuration information from the SUMA.

Refer to: Module Configuration - System Operation and Component Description (418-01 Module Configuration, Description and Operation).

-

Depressurize the air suspension system.

-

Remove the RH front fender splash shield.

Refer to: Fender Splash Shield (501-02 Front End Body Panels, Removal and Installation).

-

Position the air suspension compressor assembly.

-

NOTE: The lower retainer is located toward the front of the vehicle. Limited accessibility.

Remove the retainers.

Torque: 18 lb.ft (25 Nm)

-

Position the air suspension compressor assembly down and out of the fender.

-

Support the air suspension compressor assembly using mechanics wire.

-

.jpg) |

-

Disconnect the air suspension control module electrical connector.

.jpg) |

-

NOTE: Note the position of the components before removal.

NOTE: Air lines are color coded and must be installed in the same location from which there were removed.

Disconnect the air suspension compressor assembly air lines and remove the air suspension compressor assembly.

.jpg) |

Installation

-

To install, reverse the removal procedure.

-

When installing a new air suspension compressor, it must

be configured (using vehicle as-built data or module configuration

information retrieved earlier in this procedure). Refer to the scan tool

instructions to carry out PMI.

Refer to: Module Configuration - System Operation and Component Description (418-01 Module Configuration, Description and Operation).

-

Calibrate the suspension system. Connect the scan tool

and carry out the Ride Height Calibration routine. Follow the scan tool

directions.

General Procedures - Air Suspension System Depressurize and Pressurize

General Procedures - Air Suspension System Depressurize and Pressurize

Pressure release

Assemble the following items:

Shut off valve

Pressure regulator with gauge

R-134a low side refrigerant line fitting

Air line male quick connect fitting

Position the vehicle on a hoist...

Removal and Installation - Air Suspension Reservoir

Removal and Installation - Air Suspension Reservoir

Removal

WARNING:

Vent all air pressure from the air suspension system prior

to disconnecting or removing any air suspension components. It is

dangerous to remove air suspension components while under pressure...

Other information:

Lincoln Aviator 2020-2026 Owners Manual: Cleaning Leather Seats

Note: Follow the same procedure as cleaning leather seats for cleaning leather instrument panels and leather interior trim surfaces. For routine cleaning, wipe the surface with a soft, damp cloth and a mild soap and water solution. Dry the area with a clean, soft cloth...

Lincoln Aviator 2020-2026 Service Manual: General Procedures - Paintwork Defects and Damage

Materials Name Specification Motorcraft® Acid NeutralizerZC-1-A - Motorcraft® Alkaline NeutralizerZC-2-A - Repair NOTE: Refinishing - Environmental Damage WARNING: Before beginning any service procedure in this manual, refer to health and safety warnings in section 100-00 General Information...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Wireless Accessory Charger (If Equipped)

- Keyless Entry

- Garage Door Opener

- New on site

- Most important about car

Fastening the Seatbelts

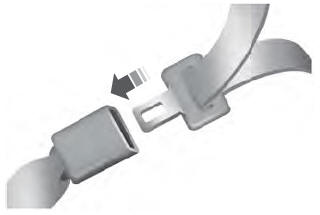

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2026 www.liaviator2.com