Lincoln Aviator 2020-2026 Service Manual / Electrical / Information and Entertainment Systems / Information and Entertainment System - General Information / Removal and Installation - Automotive Audio Bus (AAB) Cable

Lincoln Aviator: Information and Entertainment System - General Information / Removal and Installation - Automotive Audio Bus (AAB) Cable

Removal

NOTE: Removal steps in this procedure may contain installation details.

NOTE: The original equipment AAB cable is part of the wiring harness and cannot be removed. This procedure refers to replacement of the cable only by overlaying the cable.

-

Remove the loadspace trim panels.

Refer to: Loadspace Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Disconnect the AAB cable connector.

.jpg) |

-

Disconnect the subwoofer electrical connector.

.jpg) |

-

Position the subwoofer assembly to access rear connectors.

-

Remove the nut.

Torque: 80 lb.in (9 Nm)

-

Remove the bolts.

Torque: 80 lb.in (9 Nm)

-

Remove the nut.

.jpg) |

-

Disconnect the electrical connectors and remove the subwoofer assembly.

.jpg) |

Installation

-

Cut the end off the existing cable.

.jpg) |

-

Cut the end off the existing cable.

.jpg) |

-

Route the new AAB following the routing shown.

-

Secure the new AAB, as necessary, to prevent NVH concerns.

-

Secure the new AAB, as necessary, to prevent NVH concerns.

.jpg) |

-

To install, reverse the removal procedure.

Removal and Installation - Audio Unit Antenna Cable

Removal and Installation - Audio Unit Antenna Cable

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTE:

The original equipment antenna cables arepart of the wiring

harnesses and cannot be removed...

Removal and Installation - Cellular Antenna Cable

Removal and Installation - Cellular Antenna Cable

Removal

NOTE:

Removal steps in this procedure may contain installation details.

All vehicles

Lower the headliner.

Refer to: Headliner - Lowering (501-05 Interior Trim and Ornamentation, Removal and Installation)...

Other information:

Lincoln Aviator 2020-2026 Service Manual: Removal and Installation - Overhead Console

Special Tool(s) / General Equipment Interior Trim Remover Removal Starting at the back, release the clips and remove the overhead console. Disconnect the electrical connectors. Use the General Equipment: Interior Trim Remover Installation To install, reverse the removal procedure...

Lincoln Aviator 2020-2026 Service Manual: Description and Operation - Front Suspension - Overview

Overview The RWD front suspension consists of the following components: Front and rear lower arms Rear lower arm ball joints Stabilizer bar, bushings and links Ride height sensors (Vehicles with Continuously Controlled Damping (CCD) Suspension) Passive or dynamically controlled shock absorber and spring assembly (Continuously Controlled Damping (CCD)) Upper control arms Wheel bearings and wheel hubs Wheel knuckles Wheel studs The front suspension uses a double ball joint short long arm suspension system...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Locking and Unlocking

- Resetting the System

- Keyless Entry

- New on site

- Most important about car

Fastening the Seatbelts

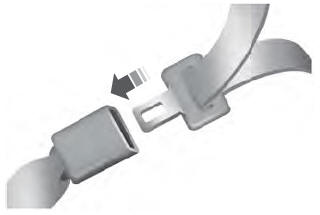

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2026 www.liaviator2.com